DIN6797 Stainless Steel External Tooth Lock Washer M6 M20 with Serrated Design

DIN6797 Stainless Steel External Tooth Lock Washer M6 M20 with Serrated Design

- توضیحات

- نظرات (0)

توضیحات

What is an External Tooth Lock Washer?

An External Tooth Lock Washer is a specialized fastener with outward-facing serrated teeth around its outer edge. When compressed between a nut/bolt head and the mating surface, these teeth bite into both materials, creating strong frictional resistance to prevent loosening from vibration, shock, or thermal cycling.

Specifications of External Tooth Lock Washer

1. Material

Carbon Steel (Grade 65Mn/1074) – High strength for general industrial use.

Stainless Steel (AISI 304/316) – Corrosion-resistant for marine/chemical environments.

Phosphor Bronze (C51000) – Conductive and non-magnetic for electronics.

Titanium – Lightweight and extreme corrosion resistance (aerospace).

2. Surface Treatment

Zinc Plating (Blue/White/Yellow) – Economical rust protection.

Black Oxide – Anti-galling and mild corrosion resistance.

Dacromet Coating – Superior corrosion protection for automotive.

Nickel Plating – For high-temperature or chemical exposure.

3. Common Sizes & Standards

Inner Diameter (ID): #2 to 1.5″ (imperial) or M2 to M36 (metric).

Outer Diameter (OD): 1.8–2.5x the bolt size (e.g., M6 washer ≈ 12mm OD).

Tooth Count: 8–16 teeth (optimized for load distribution).

Thickness: 0.8mm to 3mm (heavy-duty versions available).

Standards: DIN 6798, SAE J156, ISO 7080.

Applications of External Tooth Lock Washers

Automotive: Wheel hubs, suspension linkages, and turbocharger assemblies.

Aerospace: Engine mounts and flight control systems.

Heavy Machinery: Excavator track bolts, crusher jaw plates.

Energy Sector: Wind turbine blade bolts, solar racking systems.

Electronics: Server racks, transformer busbars.

Excellent Case: Securing Wind Turbine Blade Bolts

Scenario

A wind farm experiences frequent bolt loosening in blade root joints due to:

Extreme vibration (from wind gusts + rotor dynamics).

Thermal cycling (-30°C to +60°C).

Composite material “creep” (fiberglass hub).

Solution

Washer Selection:

Material: AISI 316 Stainless Steel (resists saltwater corrosion).

Size: M24 external tooth washer (ID 24mm, OD 45mm, 12 teeth).

Coating: Dacromet for long-term weather resistance.

Installation:

Teeth grip the steel bolt head and fiberglass hub surface.

Combined with thread-locking adhesive for redundant security.

Results

Zero Loosening Events: After 5 years of operation (vs. quarterly retorquing previously).

Prevents Micro-Movement: Teeth eliminate fretting corrosion at the joint.

Cost Savings: $200k/year reduced maintenance per turbine.

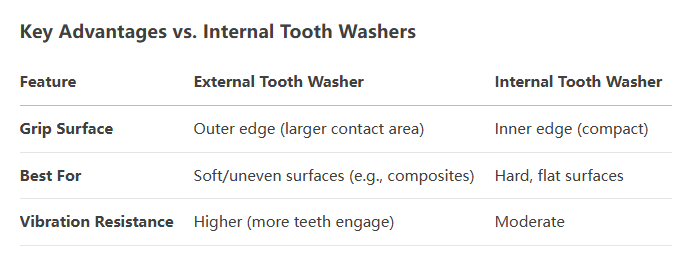

Why It Outperforms Alternatives

Distributes Load: Teeth prevent localized stress on composites.

Works with Soft Materials: Unlike split washers, won’t damage fiberglass.

Temperature Resistant: Performs across extreme thermal ranges.

Conclusion

External tooth lock washers excel in high-load, high-vibration environments where material mismatch (e.g., steel bolt + composite) demands secure, long-term fastening. The wind turbine case proves their reliability in critical renewable energy infrastructure.

نقد و بررسیها

هنوز بررسیای ثبت نشده است.