CNC Machining Aluminum Hydraulic Valve Block Superior Engineered Hydraulic Manifold Block

CNC Machining Aluminum Hydraulic Valve Block Superior Engineered Hydraulic Manifold Block

- توضیحات

- نظرات (0)

توضیحات

What is a Hydraulic Valve Block?

Materials of Hydraulic Valve Block

Carbon Steel: The most common choice, such as AISI 1018, 1020, or 1045. It offers an excellent balance of strength, machinability, and cost-effectiveness for a wide range of industrial pressures.

Stainless Steel: Often grades like 304 or 316. Used in applications requiring high corrosion resistance, such as in marine environments, the food and beverage industry, or chemical processing.

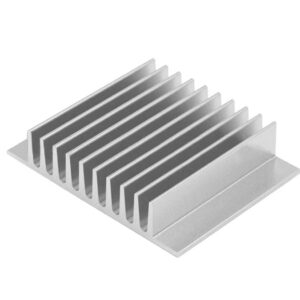

Aluminum: Alloys like 6061-T6 are popular for mobile equipment and aerospace applications where weight is a critical factor. It provides good strength-to-weight ratio and natural corrosion resistance.

Ductile Iron / Cast Iron: Used for very large or complex manifold designs where casting might be more economical than machining from a solid block. It offers good vibration damping properties.

Surface Treatments of Hydraulic Valve Block

Phosphate Coating (Parkerizing): A common and cost-effective treatment for carbon steel that provides corrosion resistance and serves as an excellent base for holding oil.

Electroless Nickel Plating (ENP): Offers a very hard, uniform, and highly corrosion-resistant surface with a clean, silver appearance. It is widely used in demanding environments.

Zinc Plating (Electrogalvanizing): Provides a sacrificial layer of zinc to protect the underlying steel from rust. It can be finished with a clear or yellow chromate passivation.

Anodizing: Used exclusively for aluminum manifolds. It creates a hard, durable, and corrosion-resistant oxide layer on the surface, which can also be dyed in different colors (though black is most common).

Paint / Powder Coating: Primarily used for additional weather protection and aesthetic purposes on the exterior of the manifold, especially in harsh outdoor environments.

Key Specifications of Hydraulic Valve Block

Operating Pressure Rating: The maximum continuous system pressure the block is designed to handle (e.g., 210 bar, 350 bar, 420 bar).

Port Sizes: The standard thread sizes for the inlet, outlet, work ports, and auxiliary connections (e.g., NPT, BSPP, SAE, Metric).

Material Grade: The specific type of metal used (e.g., AISI 1018, 6061-T6 Aluminum).

Surface Finish: The quality of the machined sealing surfaces, crucial for preventing leaks.

Cavity Configuration: The number, type, and arrangement of valve mounting cavities (e.g., for CETOP, ISO, or NFPA valves).

Internal Flow Capacity: The size and design of the internal passages, which determine the maximum flow rate with acceptable pressure drop.

Application Fields of Hydraulic Valve Block

Mobile Machinery: Excavators, cranes, loaders, and agricultural tractors.

Industrial Machinery: Plastic injection molding machines, metal press brakes, machine tools, and stamping presses.

Aerospace: Flight control systems, landing gear actuation, and cargo handling.

Marine and Offshore: Steering systems, winches, and deck machinery.

Energy Sector: Wind turbine pitch and brake control, hydroelectric power systems.

Excellent Case of Hydraulic Valve Block: Precision Press Brake

Challenge: A manufacturer of metal fabrication equipment needed to control a high-tonnage press brake used for bending sheet metal. The traditional system, with its maze of hoses and fittings, was prone to leaks, required significant maintenance, and suffered from slow response times, leading to inconsistent bend quality.

Solution: A custom-designed hydraulic valve block was engineered to integrate all directional, pressure, and flow control valves into a single, compact unit. The block was machined from high-strength carbon steel and treated with electroless nickel plating for durability in a workshop environment.

Outcome: The new system eliminated over 80% of the external piping, drastically reducing potential leak points. The optimized internal passages allowed for faster and more precise control of the hydraulic cylinders, resulting in faster cycle times and highly repeatable, accurate bends. Maintenance was simplified to checking the valves mounted on the block’s surface. This led to a significant increase in productivity, part quality, and overall machine reliability.

نقد و بررسیها

هنوز بررسیای ثبت نشده است.