Durable Stepped Gasket with Asymmetric Layers for Misaligned Flange Sealing Solutions

Durable Stepped Gasket with Asymmetric Layers for Misaligned Flange Sealing Solutions

- توضیحات

- نظرات (0)

توضیحات

What is a Stepped Gasket?

A stepped gasket is a specialized sealing component designed with multiple levels (steps) of varying thicknesses to accommodate uneven or multi-level mating surfaces. Unlike flat gaskets, stepped gaskets provide a custom-fit seal in applications where standard gaskets fail due to misalignment or pressure variations.

Key Features

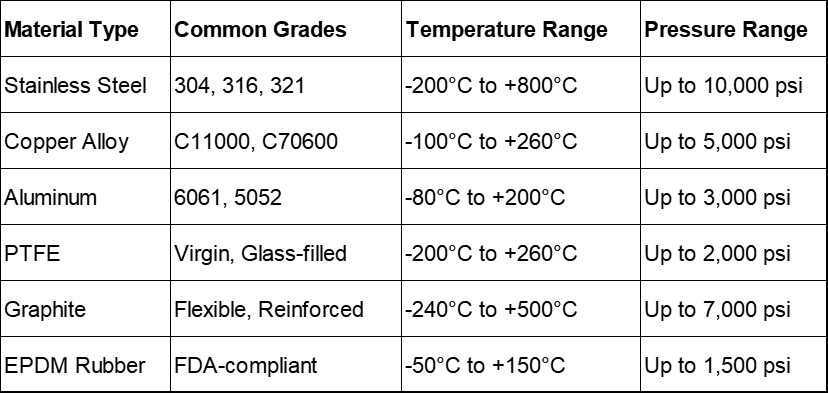

1. Materials

Metallic :

Stainless Steel (304, 316) : High corrosion resistance for chemical/petrochemical industries.

Copper/Copper Alloys : Excellent thermal conductivity for heat exchangers and engines.

Aluminum : Lightweight with good thermal performance (e.g., automotive).

Titanium : Extreme temperature/pressure resistance (aerospace, marine).

Non-Metallic :

PTFE (Teflon) : Chemical inertness for aggressive fluids.

Rubber (NBR, EPDM) : Flexibility for low-pressure sealing.

Graphite : High-temperature stability (exhaust systems, flanges).

2. Surface Treatments

Electroplating (Zinc, Nickel, Silver) : Improves corrosion resistance.

Anodizing (Aluminum) : Hardens surface and prevents oxidation.

PTFE Coating : Reduces friction and chemical adhesion.

Laser Etching : Adds anti-slip micro-patterns for better grip.

3. Applications

Automotive : Cylinder heads, exhaust manifolds.

Oil & Gas : Flange connections in pipelines.

Aerospace : Jet engine components.

HVAC/Plumbing : Pump housings, valve assemblies.

Electronics : Heat sink sealing in high-power devices.

Successful Cases

1. Automotive Industry – High-Pressure Fuel Injection Systems

Challenge: A leading automotive manufacturer faced frequent leaks in high-pressure fuel injection systems due to standard flat gaskets failing under extreme pressure and temperature fluctuations.

Solution: Custom-designed stepped gaskets with multi-layer construction were implemented, featuring varying thicknesses to accommodate uneven flange surfaces.

Result:

✔ Eliminated leaks even under 2,000+ psi pressure.

✔ Extended gasket lifespan by 3x compared to traditional designs.

✔ Improved engine efficiency by maintaining precise fuel delivery.

2. Oil & Gas – Pipeline Flange Sealing

Challenge: A major oil refinery experienced recurring leaks in pipeline flanges due to misalignment and thermal expansion.

Solution: Stepped gaskets with asymmetric thickness profiles were deployed to compensate for flange irregularities.

Result:

✔ Reduced downtime by 40% due to fewer seal failures.

✔ Enhanced safety by preventing hazardous fluid leaks.

✔ Lower maintenance costs with a 50% reduction in gasket replacements.

3. Aerospace – Jet Engine Exhaust Seals

Challenge: A jet engine manufacturer needed a reliable sealing solution for exhaust systems exposed to extreme heat and vibration.

Solution: High-temperature-resistant stepped metal gaskets with a contoured design were developed to ensure a tight seal despite thermal cycling.

Result:

✔ Achieved leak-free performance at 1,200°C+ temperatures.

✔ Reduced engine weight by optimizing gasket material and design.

✔ Increased service intervals , lowering operational costs.

These cases demonstrate how stepped gaskets solve critical sealing challenges by adapting to uneven surfaces, high pressures, and extreme temperatures—making them ideal for demanding industrial applications.

نقد و بررسیها

هنوز بررسیای ثبت نشده است.