Custom Single End Threaded Studs Partially Threaded Electronics Studs

Custom Single End Threaded Studs Partially Threaded Electronics Studs

- Descripción

- Valoraciones (0)

Descripción

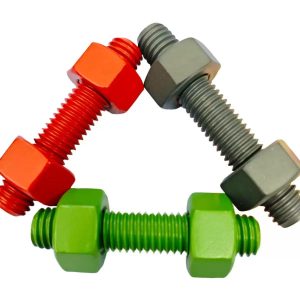

What Are Single End Threaded Studs?

Single End Threaded Studs are specialized fasteners featuring threading on one end while the opposite end remains unthreaded (typically smooth or designed for welding). These studs are engineered to provide secure anchoring in applications where one component needs permanent fixation while the other requires removable fastening. Their unique design makes them indispensable in structural, mechanical, and industrial assemblies where vibration resistance and load distribution are critical.

Materials

Single end threaded studs are manufactured from high-performance alloys to meet diverse operational demands:

Carbon Steel (Grade 4.8/8.8/10.9) – Economical option for general-purpose applications with moderate strength requirements.

Stainless Steel (A2-304/A4-316) – Corrosion-resistant solutions for chemical, marine, and food processing environments.

Alloy Steel (B7/B16) – Heat-treated variants for high-temperature/pressure applications in power plants and oil refineries.

Titanium (Grade 2/5) – Lightweight yet ultra-strong studs for aerospace and medical equipment where weight savings are crucial.

Surface Finishes

Advanced surface treatments enhance performance and longevity:

Zinc Plating (Yellow/Blue/Black) – Basic corrosion protection for indoor carbon steel studs.

Hot-Dip Galvanized – Thick zinc coating for outdoor structures and coastal applications.

Xylan/Dacromet Coating – Dry lubricant finishes providing both corrosion resistance and anti-galling properties.

Mechanical Phosphating – Creates micro-textured surface for superior paint/powder coating adhesion.

Specifications of Single End Threaded Studs

Technical parameters vary by application requirements:

Thread Standards: Metric (M6-M64), UNC/UNF (1/4″-4″), or custom thread forms like ACME.

Shank Diameter: Ranging from 3mm to 100mm with tolerance grades 6g/6H.

Length Configurations:

Short studs (20-50mm) for electronics/automotive

Medium (50-300mm) for structural steel

Long studs (300-1500mm) for civil engineering

Special Features: Some variants include:

Knurled unthreaded ends for press-fit applications

Welding pads/flanges on plain ends

Reduced shank diameters for weight optimization

Applications

These versatile fasteners serve critical roles across industries:

Heavy Machinery – Engine block assembly where one end threads into castings

Power Generation – Turbine casing installations requiring thermal expansion accommodation

Bridge Construction – Anchor bolts for seismic-resistant structural connections

Railway Systems – Permanent way fastenings with vibration-resistant properties

Semiconductor Equipment – Precision alignment studs for cleanroom installations

Premium Case: High-Speed Rail Track Fastening System

Challenge:

A national rail operator needed to upgrade aging track fasteners on a 350km/h bullet train line. Existing bolts loosened under extreme vibration, requiring weekly maintenance and creating safety hazards.

Engineering Solution:

The project specified Grade 10.9 single end threaded studs with:

Induction-hardened threads to prevent wear from micro-movements

Dacromet-coated shanks resisting rust from de-icing salts

Torque-indicating grooves for visual installation verification

Elliptical unthreaded shanks to absorb harmonic vibrations

Implementation:

The threaded ends screwed into pre-set anchor blocks cast in concrete ties

Specialized hydraulic tensioners achieved precise 450Nm preload

Patented spring washers compensated for thermal expansion

Results:

Maintenance intervals extended from 7 days to 18 months

Vibration-related failures reduced by 92%

Achieved 0.03mm maximum displacement under load

Became standard for all new high-speed lines in the network

Valoraciones

No hay valoraciones aún.