Aluminum Extrusion Connectors OEM Aluminium Profile Motor Connectors with Flexible Shaft Coupling

Aluminum Extrusion Connectors OEM Aluminium Profile Motor Connectors with Flexible Shaft Coupling

- Descripción

- Valoraciones (0)

Descripción

What Are Aluminum Extrusion Connectors?

Aluminum Extrusion Connectors are specialized hardware components designed to join, reinforce, and assemble aluminum profiles in modular structures. They enable fast, precise, and strong connections without welding, making them ideal for adjustable, lightweight, and durable frameworks in industrial, automation, and DIY applications.

Specifications of Aluminum Extrusion Connectors

1. Material

Primary Material:

6061-T6 Aluminum (high strength, excellent machinability, corrosion-resistant).

6063-T5 Aluminum (better surface finish, slightly lower strength than 6061).

Alternative Options:

Stainless Steel (for extreme environments).

Zinc Alloy (for cost-effective, high-volume production).

2. Surface Treatment

Anodizing (Clear, Black, or Colored) – Enhances corrosion resistance & aesthetics.

Powder Coating – Extra durability & color options.

Sandblasting – Improves grip & coating adhesion.

Polishing – Smooth finish for decorative applications.

3. Common Specifications

Profile Compatibility: 20×20mm, 30×30mm, 40×40mm, 80×80mm (standard T-slot sizes).

Connection Types:

Corner Brackets (90°, 45°, 135° angles).

T-Nuts & Bolts (for adjustable fastening).

End Caps & Plates (for finishing edges).

Hinges & Pivots (for movable joints).

Load Capacity: Varies by design (typically 50kg–500kg static load).

4. Applications

Industrial Automation (robot frames, conveyors, CNC machines).

Motor & Drive Systems (mounting brackets, servo motor supports).

Workstations & Ergonomics (assembly tables, tooling racks).

Renewable Energy (solar panel frames, wind turbine components).

DIY & Consumer Products (3D printers, furniture, exhibition stands).

Excellent Case: Motor Mounting Connector for Industrial Servo Motors

Challenge

A factory needed a vibration-resistant, adjustable mounting system for high-precision servo motors in an automated assembly line. The solution had to:

✔ Minimize misalignment (critical for belt/pulley systems).

✔ Dampen vibrations (to prevent motor wear).

✔ Allow quick maintenance (without disassembling the entire machine).

Solution

An aluminum extrusion-based motor mount was designed using:

Material: 40×40mm 6061-T6 aluminum profiles (rigidity + lightweight).

Connectors:

Heavy-Duty Corner Brackets (for structural stability).

Sliding T-Nuts & Locking Bolts (for micro-adjustments).

Vibration-Isolating Pads (rubber gaskets between motor & frame).

Assembly:

The motor plate was mounted on adjustable rails for fine-tuning position (±0.5mm accuracy).

Quick-release clamps enabled fast motor replacement.

Results

✔ Precision Alignment – Reduced belt slippage by 90%.

✔ Vibration Control – Motor lifespan increased by 30%.

✔ Easy Maintenance – Motor swaps completed in <3 minutes.

Industry

Packaging Automation (Servo-Driven Conveyor System)

Why Use Aluminum Extrusion Connectors for Motors?

✅ Lightweight but Strong – No unnecessary load on moving parts.

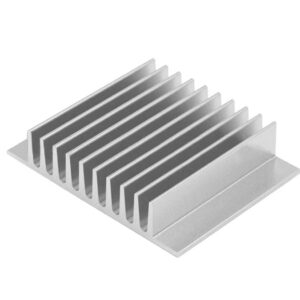

✅ Thermal Conductivity – Helps dissipate motor heat.

✅ Modularity – Easy to upgrade (e.g., adding encoders or sensors).

✅ Cost-Efficient – No welding; reusable components.

Valoraciones

No hay valoraciones aún.