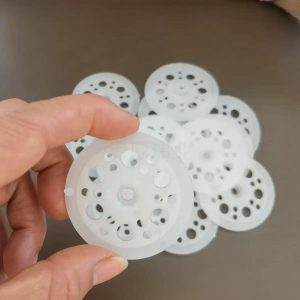

Plastic Washers Foam Screw Washers for Fixing and Supporting Foam Insulation Panels

0 out of 5

Plastic Washers Foam Screw Washers for Fixing and Supporting Foam Insulation Panels

- Descripción

- Valoraciones (0)

Descripción

What are Plastic Washers?

Plastic washers are thin, disk-shaped components with a central hole that are used to distribute the load of a threaded fastener (such as a screw or bolt). They serve as spacers, vibration reducers, or seals in various assemblies. Unlike metal washers, plastic washers offer excellent corrosion resistance, electrical insulation, and often lower cost.

Materials for Plastic Washers

Nylon (PA): High strength, good wear resistance, and excellent chemical resistance

Polyethylene (PE): Good chemical resistance and low friction

Polypropylene (PP): Excellent chemical resistance and fatigue resistance

PTFE (Teflon): Outstanding chemical resistance and low friction

PVC: Good rigidity and chemical resistance

Acetal (POM): High strength and stiffness with good dimensional stability

Polycarbonate (PC): High impact resistance and transparency options

Surface Treatments

Plain (as-molded finish)

Polished (for reduced friction)

Lubricated (for specific applications)

UV-stabilized (for outdoor use)

Colored (for identification or aesthetic purposes)

Specifications

Sizes: Typically range from M3 to M12 (metric) or #4 to 1/2″ (imperial)

Thickness: Usually 0.5mm to 3mm

Types: Flat washers, fender washers, shoulder washers, sealing washers

Standards: DIN 125, DIN 9021 (for some plastic washer variants)

Application Fields

Electrical and electronic assemblies (for insulation)

Plumbing systems (chemical resistance)

Automotive components (vibration damping)

Marine applications (corrosion resistance)

Food processing equipment (FDA-compliant materials)

Medical devices (biocompatible options)

Outdoor equipment (UV-resistant materials)

Excellent Case: Solar Panel Mounting System

Challenge: A solar energy company needed to mount panels on metal frames while preventing galvanic corrosion between aluminum frames and stainless steel hardware, and ensuring electrical isolation.

Solution: They used UV-stabilized nylon washers between all metal-to-metal contact points.

Results:

Eliminated corrosion issues, extending system lifespan

Provided necessary electrical insulation for safety

Withstood outdoor environmental conditions (UV, temperature fluctuations)

Reduced maintenance costs by 40% compared to previous metal washer solutions

Maintained structural integrity while being lightweight

The plastic washers in this application demonstrated superior performance to metal alternatives by solving multiple problems simultaneously while offering cost savings.

Valoraciones

No hay valoraciones aún.