Custom-designed Odd Shaped Gasket Sealing Component For Semiconductor Oil Gas

Custom-designed Odd Shaped Gasket Sealing Component For Semiconductor Oil Gas

- Descripción

- Valoraciones (0)

Descripción

What is an Odd Shaped Gasket?

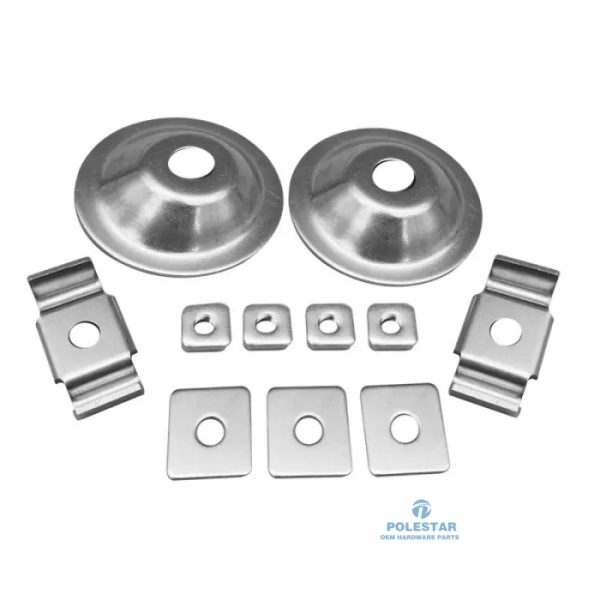

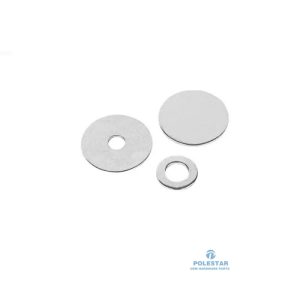

An odd-shaped gasket is a custom-designed sealing component with non-standard geometry, tailored to fit unique or irregular mating surfaces that cannot be sealed by standard round, square, or rectangular gaskets. These gaskets are precision-engineered to match complex contours, asymmetric bolt patterns, or specialized equipment requirements.

Odd Shaped Gasket Specifications

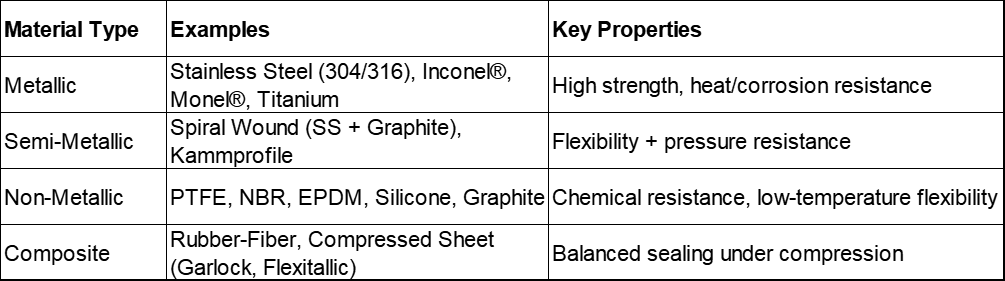

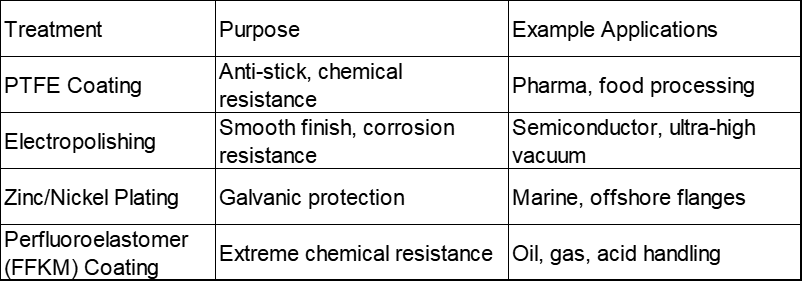

1. Common Materials

2. Key Specifications

Thickness: 0.5mm to 6mm (or thicker for high-pressure apps)

Tolerance: ±0.1mm to ±0.5mm (CNC-machined for precision)

Hardness (Rubber): 40-90 Shore A

Pressure Rating: Up to 10,000 psi (metal gaskets)

Temperature Range:

Non-metallic: -50°C to +250°C

Metallic: -200°C to +1000°C

3. Surface Treatments

4. Common Applications

Aerospace: Sealing jet engine housings with titanium gaskets

Semiconductor: Odd-shaped EMI shielding gaskets for cleanrooms

Oil & Gas: Custom RTJ gaskets for wellhead flanges

Pharma: FDA-compliant PTFE gaskets for reactor lids

Automotive: Asymmetric turbocharger gaskets

Successful Case: CNC-Machined Odd Shaped Gaskets for High-Performance Aerospace Applications

Introduction: The Challenge of Custom Gaskets in Aerospace

In the aerospace industry, gaskets play a critical role in sealing fuel systems, hydraulic lines, and engine compartments. However, standard gaskets often fail in extreme conditions—such as high pressure, vibration, and thermal cycling—leading to leaks and system failures.

A leading aerospace manufacturer faced this challenge when designing a next-generation jet engine . The engine required odd-shaped gaskets with ultra-tight tolerances and exotic materials to withstand temperatures exceeding 500°C while maintaining a perfect seal.

Traditional die-cutting and stamping methods couldn’t achieve the required precision, so the company turned to CNC machining for a solution.

The Solution: Precision CNC-Machined Odd Shaped Gaskets

1. Custom Design & Material Selection

Complex Geometry: The gasket had an asymmetrical, multi-lobed shape to fit a proprietary engine housing.

High-Temperature Material: Instead of rubber or standard PTFE, the team chose Graphite-Reinforced PEEK (Polyether Ether Ketone) for its thermal stability and chemical resistance .

2. CNC Machining Advantages

Laser-Cut Precision (±0.001″ Tolerance): CNC laser cutting ensured perfect edge quality without burrs or deformations.

Multi-Axis Machining: A 5-axis CNC mill produced complex contours and undercuts that traditional methods couldn’t achieve.

Fast Prototyping: CNC allowed rapid design iterations before final production.

3. Performance Testing & Results

Pressure Testing: The gasket maintained a leak-proof seal at 10,000 PSI .

Thermal Cycling: No degradation after 1,000+ cycles between -50°C and 500°C.

Vibration Resistance: Survived extreme engine vibrations without cracking or loosening.

Valoraciones

No hay valoraciones aún.