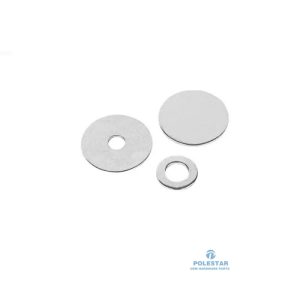

Custom Metal Washer Precise Stainless Steel Extra Thick Flat Washers

0 out of 5

Custom Metal Washer Precise Stainless Steel Extra Thick Flat Washers

Κατηγορία: Machined Washer

Ετικέτες: 3 inch metal washer, 3 metal washer, 6mm machined washers, CNC machined washer, CNC machined washers, custom washer, extra thick flat washers, flat metal washer, heavy metal washer, metal washer, metal washers, small metal washer, stainless steel washers, thick metal washer

- Περιγραφή

- Αξιολογήσεις (0)

Περιγραφή

What is a Metal Washer?

A metal washer is a small, flat metal disc with a central hole designed to distribute the load of threaded fasteners like bolts, screws, or nuts over a larger surface area. These components serve multiple purposes in mechanical, architectural, and industrial applications:

Load distribution: Prevents surface stress and material deformation by evenly spreading fastener pressure

Spacing: Acts as a spacer when fastener length exceeds material depth

Vibration absorption: Certain types help dampen vibrations in machinery

Sealing: Specialized versions with bonded materials prevent leaks in plumbing/HVAC systems

Corrosion prevention: Insulates dissimilar metals to prevent galvanic corrosion

Metal washers are manufactured through precision stamping or CNC machining processes from various metals including carbon steel, stainless steel, brass, copper, and specialized alloys.

Metal Washer – Extra Thick Flat Washers

Materials

Extra thick flat washers (3-18mm thickness) are typically made from high-strength materials including:

AISI 4140 alloy steel: Offers excellent strength and toughness

Stainless steel 316: Provides superior corrosion resistance

Carbon steel: Cost-effective option for heavy-duty applications

Inconel: For extreme temperature environments

Titanium: When high strength-to-weight ratio is required

Surface Treatments

These washers undergo specialized surface treatments to enhance performance:

Black oxide coating: Improves corrosion resistance and reduces light reflection

Zinc-nickel plating: Provides superior protection against rust

Quenching and tempering: Achieves Rockwell hardness ratings of HRC 38-42

Precision grinding: Ensures tight tolerances (±0.02mm)

Specifications

Key specifications for extra thick flat washers include:

Thickness: 3-18mm (compared to standard washers at 0.5-3mm)

Load capacity: 1,200-2,400 kN (substantially higher than standard washers)

Standards compliance: ASTM F436, ISO 7085, ASME B18.22.1

Tolerances: ±0.02mm for precision applications

Temperature resistance: Up to 1,800°F (982°C) for high-temperature variants

Application Fields

Extra thick flat washers are critical in industries requiring extreme durability:

Renewable energy: Wind turbine tower flange connections

Heavy construction: Bridge building and infrastructure projects

Mining equipment: High-vibration, high-load environments

Railway systems: For track and bridge maintenance

Offshore drilling: Saltwater-resistant applications

Aerospace: Where precision and reliability are paramount

Excellent Case: Wind Turbine Assembly

Challenge: A wind energy company was experiencing frequent bolt failures (63% failure rate) in their turbine tower flange connections due to extreme weather conditions and constant vibration10.

Solution: The company switched to 14mm thick extra flat washers made from quenched and tempered AISI 4140 alloy steel with zinc-nickel plating.

Results:

63% reduction in bolt failure rates due to improved load distribution

Extended maintenance intervals from 6 months to 2 years

Improved safety by preventing catastrophic joint failures

Cost savings from reduced downtime and replacement part requirements

Better performance in corrosive coastal environments due to specialized plating

The extra thick washers provided the necessary durability to withstand the tremendous forces and environmental challenges faced by offshore wind turbines, demonstrating how specialized washer solutions can solve critical engineering problems.

Αξιολογήσεις

Δεν υπάρχει καμία αξιολόγηση ακόμη.