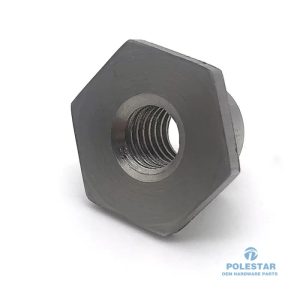

Stainless Steel Hex Keps Nuts with External Tooth Lock Washer Hexagon K Lock Nut

Stainless Steel Hex Keps Nuts with External Tooth Lock Washer Hexagon K Lock Nut

- Περιγραφή

- Αξιολογήσεις (0)

Περιγραφή

Keps Nuts: The Secure Fastening Solution with Built-In Locking

What Are Keps Nuts?

Keps nuts (also called K-lock nuts or washer nuts) are a specialized type of hex nut with an attached free-spinning external tooth lock washer. The name “Keps” comes from the brand “Kepspeed,” which originally popularized this design. The integrated washer provides a locking function that prevents loosening due to vibration, making these nuts ideal for applications where secure fastening is critical.

Unlike standard nuts, Keps nuts eliminate the need for a separate washer, speeding up assembly while maintaining vibration resistance. The washer’s teeth bite into the mating surface, creating friction that resists rotation. These nuts are commonly used in automotive, electronics, machinery, and other industries where vibration or movement could compromise fastener integrity.

Materials for Keps Nuts

Keps nuts are available in various materials to suit different environmental and mechanical requirements:

Carbon Steel (Grade 5, Grade 8) – High strength, commonly zinc-plated for corrosion resistance.

Stainless Steel (304, 316) – Excellent corrosion resistance, ideal for harsh environments.

Brass – Used in electrical and marine applications for its non-magnetic and anti-corrosive properties.

Nylon-Insert (Nyloc Variant) – Provides additional vibration resistance with a plastic locking mechanism.

Aluminum – Lightweight, used in aerospace and automotive applications.

The choice of material depends on factors such as load-bearing capacity, corrosion resistance, and temperature conditions.

Surface Finishes for Keps Nuts

To enhance durability and performance, Keps nuts can be treated with different coatings:

Zinc Plating (Yellow/Blue/Black Zinc) – Provides basic corrosion resistance and a clean appearance.

Hot-Dip Galvanizing – Heavy-duty protection for outdoor and industrial use.

Nickel Plating – Improves wear resistance and offers a polished look.

Chrome Plating – Used for decorative and high-corrosion-resistance applications.

Phosphate Coating – Enhances lubricity and corrosion resistance in automotive applications.

Passivation (for Stainless Steel) – Removes free iron particles to maximize corrosion resistance.

Specifications of Keps Nuts

Thread Sizes: Common sizes range from M3 to M12 (metric) and #4-40 to 1/2″-13 (imperial).

Locking Mechanism: External tooth lock washer (standard) or optional nylon insert for extra security.

Standards: Complies with DIN 985, ISO 7040, ASME B18.2.2.

Temperature Range: Varies by material, from -40°C to +120°C (nylon insert) up to +800°C (stainless steel).

Torque Resistance: Higher than standard nuts due to the locking washer’s grip.

Applications of Keps Nuts

Keps nuts are widely used in industries where vibration resistance and quick assembly are crucial:

Automotive: Engine components, chassis fastening, and interior panels.

Electronics: Securing circuit boards, control panels, and enclosures.

Machinery & Robotics: Preventing loosening in moving parts and motor mounts.

Aerospace: Lightweight fastening in non-critical structural components.

Furniture & Appliances: Used in assembly lines for efficient production.

HVAC & Plumbing: Securing ductwork, pipes, and electrical fixtures.

Excellent Case: Automotive Engine Mount Reinforcement

Challenge

An automotive manufacturer faced frequent loosening of standard nuts in engine mounts due to constant vibration, leading to increased warranty claims and safety concerns. Traditional lock washers and thread-locking adhesives were not providing a reliable long-term solution.

Solution

The engineering team switched to zinc-plated Grade 8 Keps nuts for all engine mount fasteners. The integrated lock washer ensured a tight grip, while the high-strength steel provided durability under extreme stress.

Results

Vibration Resistance: No reported loosening after 50,000+ miles of testing.

Faster Assembly: Eliminated the need for separate washers, reducing assembly time by 15%.

Cost Savings: Reduced warranty claims and maintenance costs by 30%.

This case demonstrates how Keps nuts provide a simple yet highly effective solution for critical fastening challenges in high-vibration environments.

Conclusion

Keps nuts offer a reliable, time-saving alternative to traditional nut-and-washer combinations, particularly in applications prone to vibration. Their versatility in material and finish options makes them suitable for industries ranging from automotive to electronics. By integrating a locking mechanism directly into the nut, they enhance both assembly efficiency and long-term fastener security.

Αξιολογήσεις

Δεν υπάρχει καμία αξιολόγηση ακόμη.