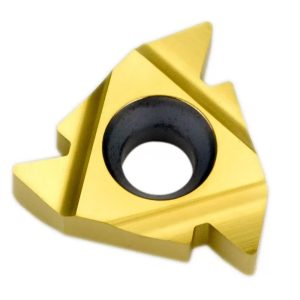

Stainless Steel Slotted Self Tapping Threaded Inserts Inner and Outer Thread Repair Insert

Stainless Steel Slotted Self Tapping Threaded Inserts Inner and Outer Thread Repair Insert

- Beschreibung

- Bewertungen (0)

Beschreibung

What Are Slotted Self Tapping Threaded Inserts?

Slotted Self Tapping Threaded Inserts are a type of fastener designed to create strong, reusable threads in soft materials such as plastic, wood, or composite materials. Unlike standard inserts that require pre-tapping, these inserts feature a slotted design and self-tapping threads that cut their own mating threads as they are installed. This makes them ideal for applications where a durable, threaded connection is needed in materials that cannot hold threads reliably on their own.

The slotted head allows for easy installation and removal using a flat-blade screwdriver, making them a convenient choice for maintenance and assembly applications. These inserts are widely used in industries where lightweight materials require reinforced threading for screws or bolts.

Materials

Slotted self tapping threaded inserts are made from various metals and alloys, chosen based on strength, corrosion resistance, and compatibility with the base material:

Brass: Excellent corrosion resistance, good conductivity, and easy machining; often used in electrical and marine applications.

Stainless Steel (304/316): High strength and corrosion resistance, ideal for harsh environments like chemical processing or outdoor use.

Carbon Steel (Zinc-Plated or Black Oxide): Economical and strong, commonly used in automotive and industrial applications where corrosion resistance is less critical.

Aluminum: Lightweight and resistant to oxidation, often used in aerospace and electronics.

Nylon (for non-metallic inserts): Used in electrical insulation applications where metal inserts could cause interference.

Surface Finishes

To enhance durability and performance, slotted self tapping threaded inserts may have different surface treatments:

Zinc Plating (Electro-Galvanized): Provides basic corrosion resistance for indoor or dry environments.

Nickel Plating: Improves wear resistance and offers a polished appearance.

Black Oxide: Adds mild corrosion resistance and reduces glare in sensitive applications.

Passivated Stainless Steel: Enhances corrosion resistance without additional coatings.

Anodized (Aluminum Inserts): Increases hardness and corrosion protection.

Specifications

Slotted self tapping threaded inserts come in various sizes and configurations to suit different applications:

Thread Size: Common metric (M3, M4, M5, M6) and imperial (#6-32, #8-32, #10-24, 1/4″-20).

Insert Length: Typically ranges from 6mm to 20mm, depending on material thickness.

Head Style: Slotted (flat-head) for screwdriver installation, though some may have hex or knurled exteriors.

Outer Thread Design: Coarse or fine self-tapping threads for optimal grip in soft materials.

Drive Type: Flat-blade (slotted), Phillips, or hex drive options for installation.

Applications

These inserts are widely used in industries where strong, reusable threads are needed in materials that would otherwise strip or wear out:

Electronics & Consumer Devices: Reinforces plastic casings for screws in laptops, routers, and appliances.

Automotive: Used in interior trim panels, dashboards, and lightweight composite parts.

Aerospace: Provides secure fastening in fiberglass and carbon fiber components.

Furniture & Woodworking: Strengthens joints in particleboard, MDF, and softwoods.

Medical Equipment: Ensures secure assembly in plastic-based medical devices.

Marine & Outdoor Equipment: Prevents thread stripping in fiberglass and plastic boat fittings.

Excellent Case: Reinforcing Plastic Housing in Electric Vehicle Battery Packs

Challenge:

An electric vehicle (EV) manufacturer needed a reliable way to secure battery pack covers made from reinforced plastic. Standard screws would strip the plastic over time due to vibration and repeated disassembly for maintenance.

Solution:

The company implemented stainless steel slotted self tapping threaded inserts into the plastic housing. The inserts were installed during molding, creating permanent, high-strength threads that could withstand repeated screw insertions without wear.

Outcome:

Enhanced Durability: The inserts prevented thread stripping, even after multiple battery pack inspections.

Corrosion Resistance: Stainless steel ensured long-term performance in harsh automotive environments.

Ease of Maintenance: The slotted design allowed quick disassembly using a standard screwdriver.

Weight Savings: Compared to metal plates or nuts, the inserts reduced overall weight while maintaining strength.

This application demonstrates how slotted self-tapping threaded inserts solve critical fastening challenges in high-performance industries, ensuring reliability and longevity in lightweight materials.

Conclusion

Slotted self tapping threaded inserts provide an efficient and durable threading solution for soft materials, offering advantages in weight savings, corrosion resistance, and ease of installation. Whether in EVs, aerospace, or consumer electronics, these inserts ensure robust and reusable threaded connections where traditional screws would fail. By selecting the right material and finish, engineers can optimize performance for any application.

Bewertungen

Es gibt noch keine Bewertungen.