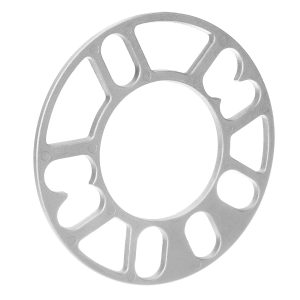

Custom AlTiN Precision Spacers Extreme Heat Resistance for Tooling Applications

0 out of 5

Custom AlTiN Precision Spacers Extreme Heat Resistance for Tooling Applications

Kategorie: Metal Spacers

Schlagwörter: 1 aluminum spacer, altin coating, altin coating for aluminum, altin coating for stainless, altin coating for steel, altin coating for titanium, aluminum spacer, cnc machined spacer, custom stainless steel spacers, Metal Spacer, Metal Spacers, Precision Spacers, round stainless steel spacers, Stainless Steel Spacers, threaded aluminum spacer

- Beschreibung

- Bewertungen (0)

Beschreibung

What Are Precision Spacers?

Precision spacers are high-accuracy components designed to maintain exact distances, align parts, or control tolerances in mechanical assemblies. They are manufactured to tight dimensional standards (often within microns) to ensure consistent performance in critical applications.

Materials for Precision Spacers

Common materials include:

Stainless Steel (AISI 304, 316, 17-4 PH) – Corrosion-resistant, high strength.

Aluminum (6061-T6, 7075) – Lightweight, good thermal/electrical conductivity.

Titanium (Grade 2, Grade 5) – High strength-to-weight ratio, biocompatible.

Brass/Bronze – Anti-galling, electrical conductivity.

Plastics (PEEK, PTFE, Delrin) – Non-conductive, chemical-resistant.

Surface Treatments

Passivation (Stainless Steel) – Removes contaminants, improves corrosion resistance.

Anodizing (Aluminum) – Enhances wear/weather resistance.

AlTiN Coating (Aluminum Titanium Nitride) – A PVD ceramic coating offering:

Extreme hardness (~3800 HV) for wear resistance.

Heat resistance (up to 900°C), ideal for high-speed or high-friction applications.

Low friction coefficient, reducing energy loss.

Electroless Nickel Plating – Uniform corrosion protection.

Black Oxide – Anti-reflective, mild corrosion resistance.

Specifications

Diameter: 1mm – 100mm (customizable).

Thickness/Length: 0.1mm – 50mm (ultra-thin shims available).

Tolerances: As tight as ±0.005mm (for aerospace/medical use).

Shapes: Round, hexagonal, square, or custom profiles.

Threaded Options: Metric/Imperial, with precise pitch control.

Applications

Aerospace: Satellite components, jet engine assemblies.

Medical: MRI machines, surgical robotics (biocompatible materials).

Semiconductors: Wafer handling, lithography equipment.

Automotive: Fuel injectors, transmission systems.

Optics/Lasers: Lens alignment, laser cavity spacing.

Excellent Case: Semiconductor Wafer Handling Robots

Challenge: A semiconductor manufacturer needed spacers for wafer-handling robots that could withstand:

Ultra-high vacuum environments.

Repeated high-speed motion (nanometer-level precision).

Chemical exposure (plasma, cleaning agents).

Solution:

Material: Titanium (Grade 5) spacers with AlTiN coating for:

Wear resistance against abrasive wafer coatings.

Thermal stability in vacuum chambers.

Chemical inertness to resist etching gases.

Tolerance: ±0.002mm to prevent misalignment.

Result:

Robot uptime increased by 40% due to reduced spacer wear.

Wafer defect rates dropped by 25% from improved positioning accuracy.

Maintenance intervals extended from weekly to quarterly.

Bewertungen

Es gibt noch keine Bewertungen.