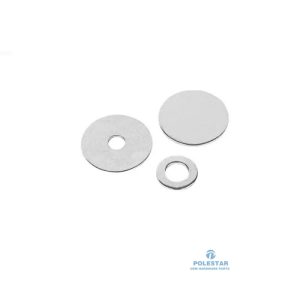

Customisable Cup Washers Galvanized Carbon Steel Cup Washer for Screw and Nut

0 out of 5

Customisable Cup Washers Galvanized Carbon Steel Cup Washer for Screw and Nut

Kategorie: Machined Washer

Schlagwörter: 3mm machined washers, 6mm machined washers, brass screw cup washers, brass screws and cup washers, CNC machined washers, CNC Machining Washers, countersunk cup washers, cup washers, cup washers mitre 10, custom cup washers, finishing cup washers, machined washer, machined washers, metal cup washers, screw cup washers, sinks with cup washers, stainless cup washers

- Beschreibung

- Bewertungen (0)

Beschreibung

What Are Cup Washers?

Cup washers (also called dome washers or curved washers) are specialized washers with a concave or cup-shaped design. They are used to distribute load, prevent fastener pull-through, and provide a smooth bearing surface in applications where a flat washer would not suffice. Their curved shape helps maintain tension and reduces stress on soft or fragile materials.

Materials of Cup Washers

Steel (Carbon steel, Stainless steel) – High strength, corrosion-resistant (stainless steel preferred for outdoor use).

Aluminum – Lightweight, corrosion-resistant, used in aerospace and electronics.

Brass – Corrosion-resistant, non-sparking, used in electrical and marine applications.

Nylon/Plastic – Insulating, lightweight, used in electronics and non-conductive applications.

Surface Treatments

Zinc Plating – Common for steel washers, improves corrosion resistance.

Galvanization – Extra corrosion protection for harsh environments.

Anodizing (for aluminum) – Enhances durability and appearance.

Passivation (for stainless steel) – Removes surface contaminants, improves rust resistance.

Powder Coating – Adds color and extra protection (used in architectural applications).

Specifications

Inner Diameter (ID): Matches bolt size (e.g., M4, M6, 1/4″, 3/8″).

Outer Diameter (OD): Typically 1.5x to 3x the bolt diameter.

Thickness: Varies (e.g., 1mm to 5mm).

Shape: Concave (cup depth varies for different load distributions).

Applications

Construction: Roofing, cladding, and metal framing to prevent fastener pull-through.

Automotive: Securing upholstery, trim panels, and wiring harnesses.

Electronics: Protecting PCB mounts and insulating connections.

Furniture: Reinforcing joints in particleboard or MDF.

Marine: Preventing corrosion in saltwater environments (stainless steel or brass).

Excellent Case: Solar Panel Mounting

Scenario: A solar energy company needs to secure photovoltaic panels to aluminum roof rails without damaging the thin panel frames.

Solution:

Material Choice: Stainless steel cup washers (corrosion-resistant, durable).

Installation:

Cup washers are placed under bolt heads when attaching solar panels to mounting rails.

The concave shape distributes clamping force evenly, preventing frame deformation.

Result:

The panels remain securely fastened even under wind and thermal expansion.

No cracking or stress fractures in the aluminum frames.

Benefits:

✔ Prevents material damage – Distributes load over a wider area.

✔ Weather-resistant – Stainless steel withstands rain, UV, and temperature changes.

✔ Long-term reliability – Reduces maintenance needs in solar farms.

Bewertungen

Es gibt noch keine Bewertungen.