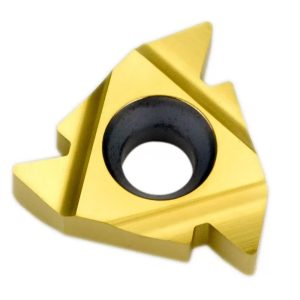

Custom Brass Thread Inserts for 3d Printed Parts Thread Inserts for Metal M3 M5 M8

0 out of 5

Custom Brass Thread Inserts for 3d Printed Parts Thread Inserts for Metal M3 M5 M8

- Beschreibung

- Bewertungen (0)

Beschreibung

Brass Thread Inserts are precision-engineered threaded reinforcement components designed to provide durable, wear-resistant threads in softer materials (such as plastic, aluminum, or wood) or to repair stripped threads. Made from brass alloy, they offer excellent corrosion resistance, electrical conductivity, and thermal stability, making them ideal for applications requiring repeated assembly/disassembly.

Specifications of Brass Thread Inserts

1. Material

Primary Alloy: Free-cutting brass (CZ121/C36000) or lead-free brass (CZ128).

Key Properties: High machinability, corrosion resistance, and anti-galling properties.

2. Surface Treatment

Natural Brass: No coating (suitable for general use).

Nickel-Plated: Enhanced corrosion resistance for harsh environments.

Zinc-Coated: Improved anti-oxidation for outdoor applications.

3. Common Specifications

Thread Types: Metric (M2–M12), UNC/UNF, BSP, or custom threads.

Installation Methods: Press-fit, ultrasonic insertion, or thermal expansion.

Standards: DIN 796, DIN 797, or ISO 9001-certified manufacturing.

4. Applications of Brass Thread Inserts

Electronics: PCB mounts, heat sinks, and connector housings.

Automotive: Engine components, sensors, and interior trim fastening.

Aerospace: Lightweight assemblies requiring vibration resistance.

Industrial Machinery: Hydraulic fittings and plastic/metal hybrid joints.

Excellent Case: Reinforcing Plastic Housing in Automotive Sensors

Challenge:

An automotive manufacturer faced frequent thread stripping in nylon sensor housings due to vibration and repeated screw adjustments during maintenance.

Solution:

Installed nickel-plated brass thread inserts (M4 size) into the nylon housing using thermal insertion.

Benefits:

Durability: Withstood 50+ assembly cycles without wear.

Vibration Resistance: Eliminated loosening issues in high-shock environments.

Corrosion Protection: Nickel plating prevented degradation from road salt and moisture.

Result:

Reduced warranty claims by 90% and extended sensor lifespan by 3 years.

Key Advantages Summary

✔ Material Versatility – Compatible with plastics, metals, and composites.

✔ Long-Term Cost Savings – Eliminates the need to replace entire components.

✔ Customizable – Available in non-standard sizes for specialized applications.

Bewertungen

Es gibt noch keine Bewertungen.