Custom Metal Shoulder Washer Stainless Steel Brass Copper Aluminum Washers

Custom Metal Shoulder Washer Stainless Steel Brass Copper Aluminum Washers

- Description

- Reviews (0)

Description

A metal shoulder washer is a type of spacer or bushing with a flanged (shoulder) design, providing insulation, alignment, or wear resistance in mechanical assemblies. The shoulder prevents over-insertion and distributes load.

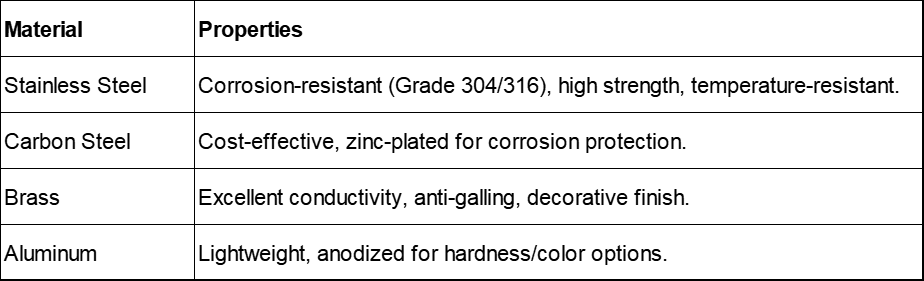

Common Materials

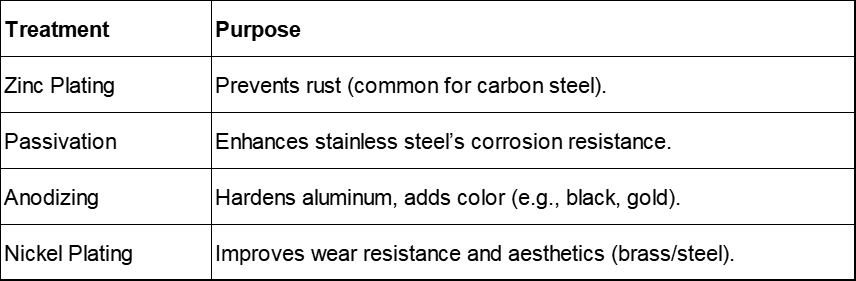

Surface Treatments

Other surface treatment like DLC, PVD,Ceramic plating,Electrophoresis,Dipping Varnishing,Powder Coating and etc can be customized.

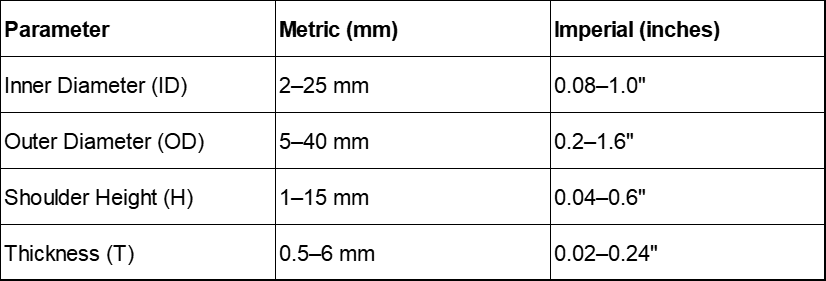

Standard Sizes

Key Applications

Electronics: Grounding washers, PCB standoffs.

Automotive: Engine mounts, vibration isolation.

Machinery: Shaft alignment, bearing spacers.

HVAC/Plumbing: Pipe supports, anti-corrosion barriers.

Excellent Case: Metal Shoulder Washer in Automotive Electrical Systems

Application: Securing Wiring Harnesses in Vehicles

Problem: In automotive electrical systems, wiring harnesses must be securely fastened to prevent vibration-induced wear, short circuits, or disconnections. Standard flat washers and screws can:

Cut into wire insulation due to sharp edges.

Loosen over time from engine vibrations.

Cause electrical interference if metal-to-metal contact occurs.

Solution: Metal Shoulder Washer

A stainless steel shoulder washer was used to mount a wiring harness bracket in a high-vibration zone near the engine.

Why It Worked:

✅ Insulation Protection – The smooth, rounded shoulder prevented abrasion against wire insulation.

✅ Vibration Resistance – The extended sleeve kept the fastener aligned, reducing loosening.

✅ Electrical Isolation – The non-conductive nylon insert (if used) prevented grounding issues.

✅ Corrosion Resistance – Stainless steel construction endured heat, moisture, and road salts.

Result:

Zero wire damage reported after 50,000+ miles of testing.

No fastener loosening , eliminating maintenance downtime.

Improved reliability in harsh environments.

Key Takeaway:

Metal shoulder washers are ideal for high-vibration, high-wear applications where protection and durability are critical. Other great uses include:

Industrial machinery (guarding against metal-on-metal wear).

Aerospace (isolating components from electrical interference).

Marine equipment (resisting saltwater corrosion).

Reviews

There are no reviews yet.