Custom Dowel Pins Press-fit h6 m6 Heavy-duty Machinery Alignment

Custom Dowel Pins Press-fit h6 m6 Heavy-duty machinery alignment

- Description

- Reviews (0)

Description

Custom Dowel Pins Press-fit h6 m6 Heavy-duty Machinery Alignment

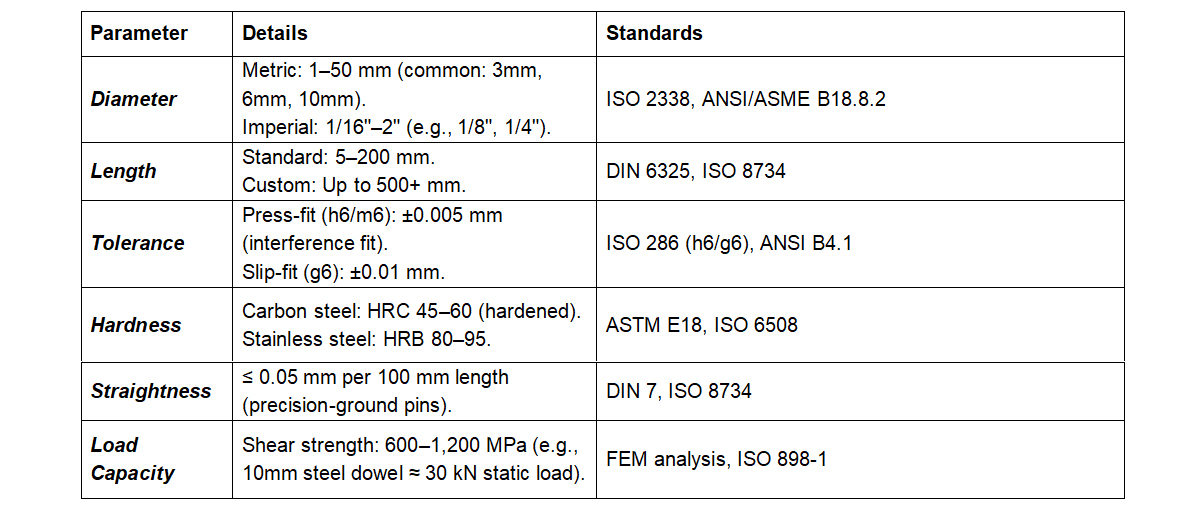

Key Specifications

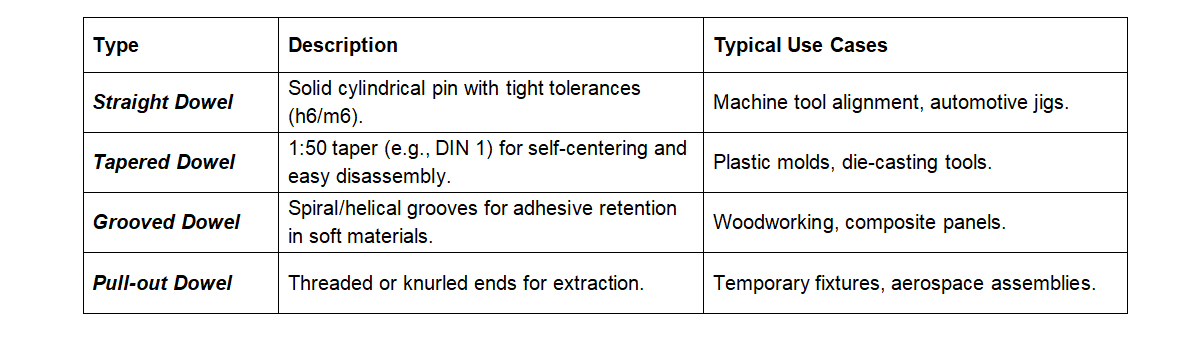

Common Types & Applications

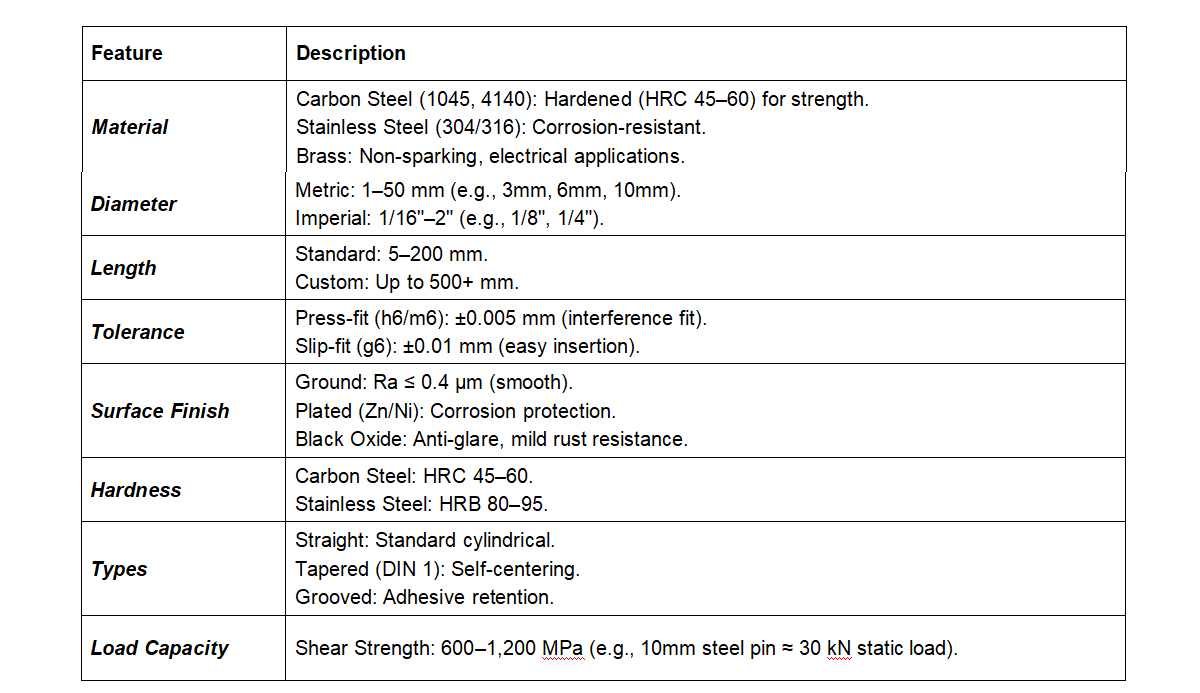

Key Features of Dowel Pins

Applications

✔ Precision Alignment : CNC machines, jigs, fixtures.

✔ Mechanical Joints : Automotive transmissions, gearboxes.

✔ Corrosive Environments : Marine, chemical processing (SS 316).

✔ Quick Assembly/Disassembly : Tapered dowels in molds.

Example Product

Part No. : DP-1045-08×40

Material : Carbon Steel 1045 (hardened).

Size : 8mm dia × 40mm length.

Tolerance : h6 (press-fit).

Surface : Ground + zinc-plated.

Use : Heavy-duty machinery alignment.

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Reviews

There are no reviews yet.