Custom Self-tapping Threaded Bushing Insert Superior Quality Stainless Steel Bushing Insert

0 out of 5

Custom Self-tapping Threaded Bushing Insert Superior Quality Stainless Steel Bushing Insert

Category: Threaded Inserts

Tags: 1 4 20 threaded insert, 1/2 threaded inserts, 1/4 in threaded insert, 3 8 threaded insert, 5/16 threaded inserts, bushing insert, m3 threaded insert, m5 threaded inserts, m8 threaded insert, stainless steel threaded inserts, stainless threaded inserts, threaded bushing insert, threaded insert, threaded insert 1 4 20, threaded insert 1/4, threaded insert 3/8, threaded insert 5/16, threaded insert m3, threaded insert m4, threaded insert metal, threaded insert stainless, threaded insert stainless steel, threaded inserts

- Description

- Reviews (0)

Description

What is a Threaded Bushing Insert?

A threaded bushing insert is a type of fastener used to create strong, durable, and wear-resistant threads in soft materials or to repair stripped or damaged threads in existing components. They are installed into a pre-drilled or tapped hole, providing a permanent and often stronger alternative to a native thread. Think of it as a durable sleeve that you install into a base material, which then accepts a standard screw or bolt.

Common Materials of Threaded Bushing Insert

Stainless Steel: Offers excellent corrosion resistance and good strength. Common grades are 303 and 304 for general use, and 316 for marine or chemical environments.

Carbon Steel: Known for its high strength and is often coated with a zinc or black oxide finish to resist corrosion.

Brass: Provides good corrosion resistance, especially in marine applications, and is electrically conductive and non-magnetic.

Aluminum: Used for its lightweight properties and good corrosion resistance in non-high-strength applications.

High-Strength Alloys: Such as Inconel or Hastelloy, used in extreme environments involving high temperatures or intense corrosion.

Common Surface Treatments

Zinc Plating: A common, cost-effective finish that provides good corrosion resistance.

Black Oxide: Offers a mild corrosion resistance and reduces light glare; mainly used for appearance and minimal protection.

Cadmium Plating: Provides excellent corrosion resistance and lubricity, though its use is declining due to environmental concerns.

Nickel Plating: Offers a hard, smooth surface with good corrosion and wear resistance.

Passivation: A chemical process for stainless steel that enhances its natural corrosion-resistant oxide layer.

Key Specifications

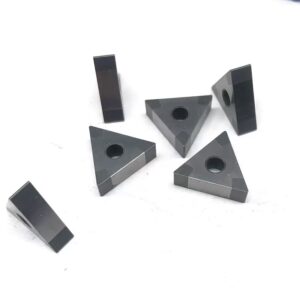

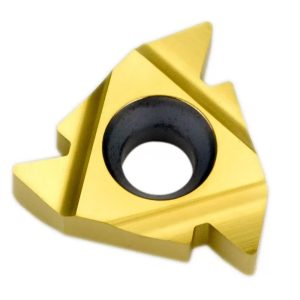

Insert Type: Helical coil (wire), solid, spiral, or key-locked.

Thread Size: The internal thread (e.g., M4, M6, 1/4″-20, 5/16″-18) and the external thread for the host material.

Length/Diameter: The physical dimensions of the insert itself.

Installation Method: Whether it is pressed in, screwed in, ultrasonically installed, or requires a special tool (like a tang break-off tool for helical coil inserts).

Drive Type: The method of installation, such as internal hex, external hex, or spline.

Application Fields

Aerospace Industry: Extensively used in aluminum and composite airframe structures to provide durable, lightweight threads.

Automotive Manufacturing: Used in engine blocks, transmission housings, and aluminum chassis components.

Consumer Electronics: Provide strong threads in plastic housings for assembly screws.

Industrial Machinery: For repairing stripped threads in expensive machine parts, saving them from being scrapped.

Marine Equipment: Brass and stainless steel inserts are used to combat corrosion in a saltwater environment.

Mold Making: Used to create durable threads in mold plates and components.

Excellent Case: Engine Cylinder Head Repair

A high-performance automotive shop is rebuilding an engine. During disassembly, one of the spark plug threads in the aluminum cylinder head is found to be cross-threaded and damaged. Instead of replacing the entire, expensive cylinder head, the technician performs a repair.

They drill out the damaged thread, tap new threads with a specific size, and install a high-temperature, stainless steel threaded bushing insert (often called a helicoil in this context). The insert is coated with a high-temperature anti-seize compound and threaded into the newly tapped hole. The installation tool is used to break off the tang at the bottom of the insert.

The result is a brand new, perfectly sized spark plug thread that is actually more robust and wear-resistant than the original aluminum thread. The engine is reassembled with a new spark plug torqued to specification, restoring the vehicle to full functionality at a fraction of the cost and time of a cylinder head replacement. This demonstrates the insert’s critical role in providing a reliable, cost-effective, and permanent repair solution.

Reviews

There are no reviews yet.