Custom Small CNC Machining Parts With Versatile Material Compatibility

Custom Small CNC Machining Parts With Versatile Material Compatibility

- الوصف

- مراجعات (0)

الوصف

What is Small CNC Machining?

Small CNC Machining refers to the use of Computer Numerical Control (CNC) machines to manufacture precision parts with small dimensions , typically ranging from a few millimeters to several centimeters in size. These machines follow digitally programmed instructions (G-code) to cut, drill, mill, or turn materials into highly accurate components with tight tolerances (often within ±0.005 mm or better).

Key Characteristics of Small CNC Machining:

High Precision & Tight Tolerances

Ideal for micro-machining (e.g., tiny gears, medical implants, electronics components).

Achieves sub-millimeter accuracy for complex geometries.

Versatile Material Compatibility

Works with metals (aluminum, stainless steel, titanium), plastics (ABS, PEEK, Delrin), and composites .

Advanced CNC Techniques

Utilizes micro-milling, Swiss turning, wire EDM, and laser machining for intricate details.

Supports multi-axis machining (3-axis, 4-axis, or 5-axis) for complex shapes.

Automated & Repeatable Production

Once programmed, CNC machines produce identical small parts with minimal human intervention.

Suitable for prototyping, low-volume, and high-volume manufacturing .

Applications of Small CNC Machining

Small CNC machining is widely used in industries requiring precision, including:

Electronics & Consumer Goods

Smartphone components (e.g., housings, connectors).

Laptop parts (e.g., heat sinks, brackets).

Wearable devices (e.g., watch cases, buttons).

الطب وطب الأسنان

Surgical instruments (e.g., forceps, scalpel handles).

Implants (e.g., titanium bone screws).

Dental prosthetics (e.g., crowns, bridges).

Automotive & Aerospace

Engine components (e.g., fuel injectors, pistons).

UAV (drone) parts.

Lightweight aerospace brackets.

Industrial & Robotics

Precision gears, shafts, and actuators.

Robotic arm joints and connectors.

Prototyping & Custom Parts

Rapid prototyping for product development.

Custom jigs, fixtures, and tooling.

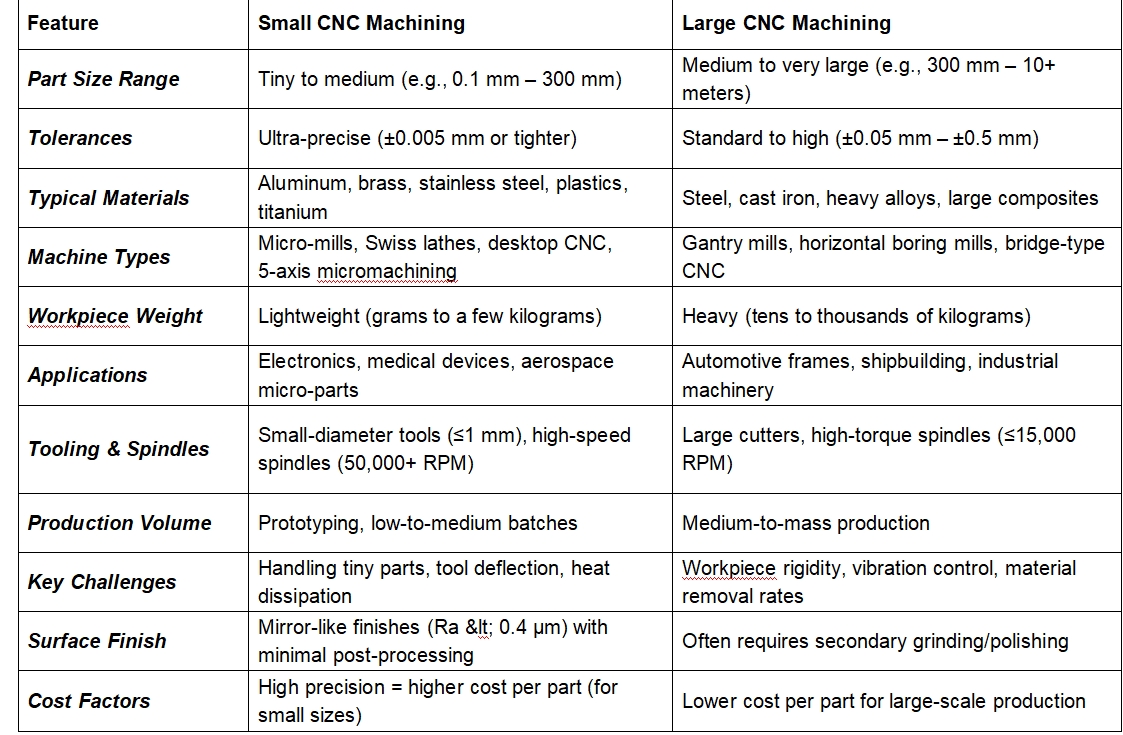

Small CNC Machining vs. Large CNC Machining: Key Differences

Summary of Differences:

Precision vs. Scale :

Small CNC: Focus on micro-scale accuracy and intricate details.

Large CNC: Prioritizes material removal rates and structural integrity.

Machinery :

Small CNC uses compact, high-speed machines (e.g., DATRON, Kern Micro).

Large CNC relies on heavy-duty, high-power machines (e.g., Mazak, DMG MORI).

Industries :

Small CNC: Medical, aerospace, electronics .

Large CNC: Energy, construction, heavy equipment .

Tooling :

Small CNC tools are fragile but ultra-precise .

Large CNC tools are robust but less precise .

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

الطب وطب الأسنان: الأدوات الجراحية، والأجهزة القابلة للزرع، والمثبتات الدقيقة.

الإلكترونيات: الموصلات الدقيقة، وأغلفة المستشعرات، وحوامل ثنائي الفينيل متعدد الكلور.

الفضاء والدفاع: الأقواس خفيفة الوزن، ومكونات الطائرات بدون طيار، والمثبتات المتخصصة.

السيارات: قطع غيار حقن الوقود، والمثبتات المخصصة، ومكونات السيارات الكهربائية.

لماذا تختارنا؟

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

المراجعات

لا توجد مراجعات بعد.