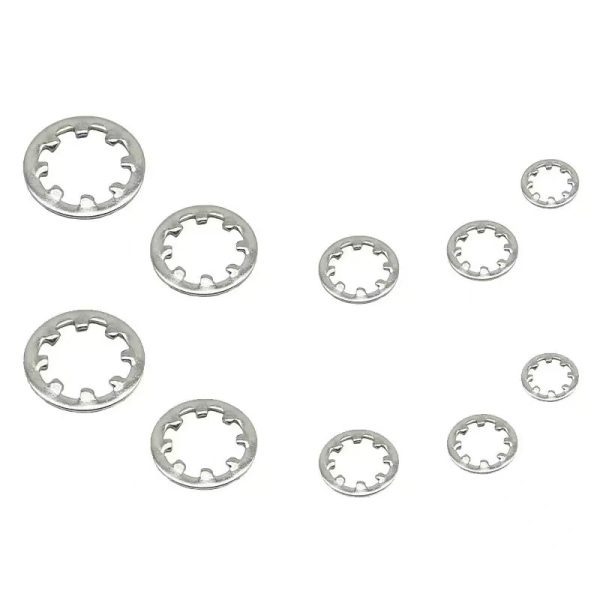

Internal Tooth Lock Washer SS304 Stainless Steel Tooth Lock Washer

Internal Tooth Lock Washer SS304 Stainless Steel Tooth Lock Washer

- الوصف

- مراجعات (0)

الوصف

What is an Internal Tooth Lock Washer?

An Internal Tooth Lock Washer is a type of locking washer designed with serrated teeth bent inward toward the center hole. When compressed under a nut or bolt head, the teeth dig into the mating surface and the fastener, creating friction and mechanical resistance to prevent loosening caused by vibration or thermal cycling.

Specifications of Internal Tooth Lock Washer

1. Material

Carbon Steel (Grade 65Mn/1074) – Standard for general applications.

Stainless Steel (AISI 304, 316) – Corrosion-resistant for harsh environments.

Phosphor Bronze (C51000) – Used in electrical applications for conductivity.

Beryllium Copper – Non-sparking and high fatigue resistance.

2. Surface Treatment

Zinc Plating (Blue/White/Yellow) – Basic corrosion protection.

Black Oxide – Improves wear resistance and reduces glare.

Passivation (Stainless Steel) – Enhances corrosion resistance.

Nickel Plating – For chemical or marine exposure.

3. Common Sizes & Standards

Inner Diameter (ID): #4 to 1″ (imperial) or M3 to M24 (metric).

Outer Diameter (OD): Typically 1.5–2x the bolt size.

Tooth Count: 6–12 teeth (varies by size).

Thickness: 0.5mm to 2.5mm.

Standards: DIN 6797, NASM 35338, or custom designs.

Applications of Internal Tooth Lock Washers

السيارات: Engine components, brake systems, and exhaust mounts.

الإلكترونيات: Securing terminal blocks, PCB standoffs, and heat sinks.

Aerospace: Avionics and vibration-prone assemblies.

Industrial Machinery: Pumps, motors, and conveyor systems.

HVAC & Plumbing: Pipe flanges and refrigerant line fittings.

Excellent Case: Securing High-Vibration Industrial Fan Blades

Scenario

A manufacturer of industrial exhaust fans faces recurring failures due to blade-attachment bolts loosening from constant vibration, leading to imbalance and catastrophic blade detachment.

Solution

Washer Selection:

Material: Stainless Steel AISI 316 (resists humid/chemical exposure).

Size: M10 internal tooth washer (ID 10mm, OD 20mm, 8 teeth).

Surface Treatment: Passivated to prevent galvanic corrosion.

Installation:

Placed under the nut of each fan blade bolt.

Teeth bite into both the blade hub (aluminum) and nut (steel), creating a mechanical lock.

Result

Eliminates Bolt Loosening: Teeth maintain grip even under 10,000 RPM vibrations.

Extends Maintenance Intervals: No retorquing required for over 2 years of operation.

Prevents Costly Failures: Zero incidents of blade detachment post-implementation.

Why It’s Superior to Alternatives

Space-Efficient: Thinner than split or helical lock washers.

Positive Locking: Teeth provide mechanical resistance (unlike friction-only flat washers).

Material Versatility: Works with soft (aluminum) or hard (steel) surfaces.

Conclusion

Internal tooth lock washers are ideal for high-vibration, high-load, or safety-critical applications where traditional washers fail. The industrial fan case demonstrates their durability, simplicity, and cost-effectiveness in preventing catastrophic failures.

المراجعات

لا توجد مراجعات بعد.