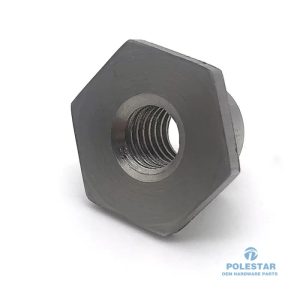

High Quality Plastic Knob Nut Plum Bakelite Hand Tighten Thread Star Knob Nut

High Quality Plastic Knob Nut Plum Bakelite Hand Tighten Thread Star Knob Nut

- الوصف

- مراجعات (0)

الوصف

What is a Knob Nut?

A knob nut, also known as a thumb nut or wing nut, is a type of fastener designed to be easily tightened and loosened by hand without the need for tools. It typically features wings or a knurled, rounded head that provides a grip for the user’s fingers. The base of the nut is threaded internally to screw onto a matching bolt or threaded rod. Its primary purpose is to allow for the quick assembly, disassembly, and adjustment of components in applications where tools are inconvenient or where frequent access is required.

Materials

Knob nuts are manufactured from various materials to meet different requirements for strength, corrosion resistance, and aesthetics. Common materials include:

Nylon Plastic: Lightweight, corrosion-proof, electrically insulating, and cost-effective. Offers good resistance to chemicals and vibrations.

Zinc Die-Cast Alloy: (Such as Zamak) Provides good strength and durability for a metal nut. Often used with a plating finish.

Stainless Steel: (Typically grades 304 or 316) Offers high strength and excellent corrosion resistance for demanding or outdoor environments.

Brass: Valued for its corrosion resistance, good electrical conductivity, and classic appearance, often used in decorative applications.

Aluminum: Lightweight and corrosion-resistant with a good strength-to-weight ratio.

Surface Finishes

Surface treatments are applied to metal knob nuts to enhance their properties and appearance.

Chrome Plating: Provides a bright, shiny, silvery finish that is highly corrosion-resistant and easy to clean.

Nickel Plating: Offers a similar bright finish with good corrosion and wear resistance.

Zinc Plating: A common and economical finish for steel parts, providing good rust protection. Often comes in clear (blue) or yellow chromate.

Powder Coating: Applied for durability and color, often used on aluminum knobs for aesthetic matching.

Polished/Brushed Metal: A mechanical finish for stainless steel or brass to achieve a specific aesthetic, from a mirror polish to a satin brush.

Specifications

Knob nuts are defined by several key specifications to ensure a proper fit and function:

Thread Size: The internal thread is the most critical spec, given in metric (e.g., M6, M8) or imperial (e.g., 1/4″-20, 5/16″-18) measurements.

Overall Dimensions: This includes the diameter and height of the knob, which determines the grip and torque a user can apply.

Wing Style: The design can range from small “ears” or wings to a full, rounded knurled head for maximum grip.

Drive Style: While most are hand-tightened, some feature a hex or slot at the top to allow for a tool to apply additional torque if needed.

Application Fields

The tool-free convenience of knob nuts makes them ideal for a wide range of applications:

Furniture and Cabinetry: For securing shelves, doors, table legs, and adjustable components in ready-to-assemble (RTA) furniture.

Industrial Equipment: Used on access panels, machine guards, and adjustable stops for quick maintenance and operational changes.

Electronics and Audio Equipment: For securing rack-mounted gear, amplifier covers, and access panels to internal components.

Automotive and Marine: In non-critical areas for securing compartments, covers, or accessories where vibration resistance is needed.

Consumer Products: Found on sporting equipment, musical instruments, and appliances for easy user adjustment.

Excellent Use Case: Professional Audio Amplifier Rack

A superb application of a knob nut is in securing heavy professional audio amplifiers into a standard 19-inch equipment rack. A threaded metal rack rail is installed on either side of the rack. The amplifier has flanges with oversized holes that align with these rails.

Instead of struggling with screws in tight spaces, the technician uses large, knurled, metal knob nuts. They simply slide the amplifier into the desired position, reach to the front of the rack flanges, and screw the knob nuts onto the threaded posts protruding from the rack rail. The large, grippy surface of the knob nut allows them to tighten the amplifier securely against the rails with firm hand pressure, ensuring excellent electrical contact and mechanical stability.

This design allows for incredibly fast installation, removal, or repositioning of valuable equipment without ever needing to find a screwdriver, significantly speeding up setup times for live sound engineers and in recording studios. The robust metal construction of the knob nut ensures it can withstand the weight and vibration of the equipment.

المراجعات

لا توجد مراجعات بعد.