Custom 1.8 T head Bolt Tool Torque Specs Bolt Tee Head lmtv For Automotive Parts

Custom 1.8 T head Bolt Tool Torque Specs Bolt Tee Head lmtv For Automotive Parts

- Description

- Reviews (0)

Description

Custom 1.8 T head Bolt Tool Torque Specs Bolt Tee Head lmtv For Automotive Parts

What is a T-Head Bolt?

A T-head bolt (also called a hammerhead bolt ) is a specialized fastener with a T-shaped head designed to fit into a T-slot track or channel . The head slides into the slot and is then secured in place with a nut, preventing rotation during tightening. This design makes T-head bolts ideal for applications requiring adjustability, strong clamping force, and easy assembly/disassembly .

Materials of T-Head Bolts

T-head bolts are available in various materials to suit different environments and load requirements:

Carbon Steel (Grade 4.8, 8.8, 10.9) – Standard strength, cost-effective, suitable for general industrial use.

Stainless Steel (A2/304, A4/316) – Corrosion-resistant, ideal for marine, food processing, and chemical industries.

Alloy Steel (4140, 4340) – High tensile strength, used in heavy machinery and automotive applications.

Brass & Aluminum – Lightweight, non-magnetic, used in electrical and decorative applications.

Surface Finishes & Coatings

To enhance durability and corrosion resistance, T-head bolts can have different surface treatments:

Zinc Plating (Yellow/White Zinc) – Basic corrosion protection for indoor use.

Hot-Dip Galvanizing – Thick zinc coating for outdoor and harsh environments.

Black Oxide – Improves wear resistance and provides a sleek appearance.

Dacromet (Geomet® Coating) – High corrosion resistance without hydrogen embrittlement.

Passivation (for Stainless Steel) – Enhances rust resistance by removing free iron from the surface.

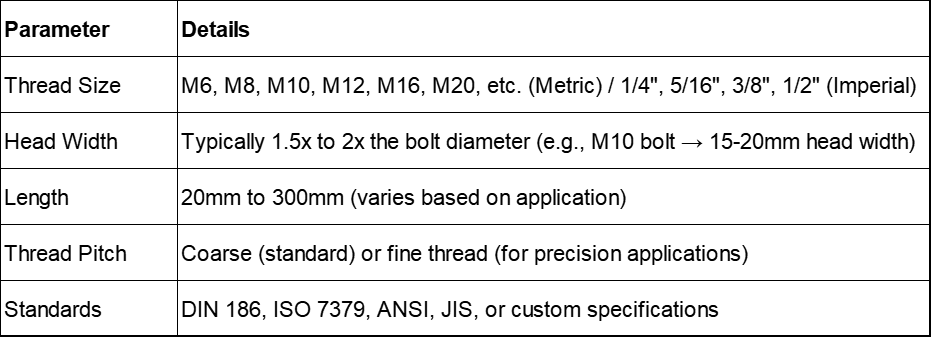

Specifications & Dimensions

T-head bolts come in standard and custom sizes. Common specifications include:

Applications of T-Head Bolts

T-head bolts are widely used in industries requiring adjustable clamping, secure fastening, and easy assembly :

Machinery & Automation – Used in T-slot framing systems for CNC machines, robotic arms, and assembly lines.

Construction & Metal Fabrication – Secures structural beams, railings, and modular building systems.

Automotive & Aerospace – Fastens engine components, chassis parts, and aircraft fixtures.

Furniture & Workbenches – Provides adjustable clamping in modular furniture and workstations.

Marine & Offshore – Stainless steel T-head bolts resist saltwater corrosion in shipbuilding and docks.

Case Examples

Case 1: Industrial CNC Machine Assembly

A manufacturer uses M12 stainless steel T-head bolts to secure aluminum extrusions in a CNC machine frame. The T-slot design allows for quick adjustments without disassembling the entire structure.

Case 2: Modular Warehouse Shelving

A logistics company installs hot-dip galvanized T-head bolts in steel shelving units. The bolts slide into T-slots, enabling easy reconfiguration as storage needs change.

Case 3: Marine Dock Construction

A shipyard uses A4/316 stainless steel T-head bolts to assemble floating docks. The corrosion-resistant bolts withstand saltwater exposure without rusting.

T-head bolts are versatile, strong, and adjustable fasteners ideal for T-slot applications in machinery, construction, automotive, and marine industries. Available in carbon steel, stainless steel, and alloy variants , they can be customized with different coatings for enhanced durability. Their slotted head design ensures secure clamping and easy installation, making them a preferred choice for modular and heavy-duty applications .

Reviews

There are no reviews yet.