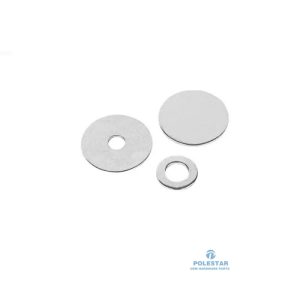

Metal Bonded Sealing Washer Drain Hose Rubber Nylon Sealing Washers Copper Dowty

Metal Bonded Sealing Washer Drain Hose Rubber Nylon Sealing Washers Copper Dowty

- Description

- Reviews (0)

Description

Metal Bonded Sealing Washer Drain Hose Rubber Nylon Sealing Washers Copper Dowty

What is a Metal Bonded Sealing Washer?

Metal Bonded Sealing Washer, a sealing washer, also known as a gasket or seal ring, is a mechanical seal that fills the space between two or more mating surfaces to prevent leakage of fluids (such as liquids or gases) or to prevent the ingress of contaminants. It is commonly used in various applications, including automotive, plumbing, machinery, and aerospace industries.

Materials of Metal Bonded Sealing Washer

Rubber : Natural rubber, nitrile rubber (NBR), silicone rubber, EPDM rubber, and fluorocarbon rubber (Viton) are widely used. Rubber sealing washers offer good flexibility, elasticity, and sealing performance. For example, NBR is resistant to oil and fuel, making it suitable for automotive engines; silicone rubber has excellent high – temperature resistance and is used in electrical and food – grade applications.

Metal : Materials like copper, aluminum, stainless steel, and brass are used. Metal sealing washers are often used in high – pressure and high – temperature applications. Copper washers are soft and can conform well to surfaces, providing a reliable seal. Stainless steel washers are corrosion – resistant and suitable for harsh environments.

Plastic : Polyethylene, polypropylene, and PTFE (Teflon) are common plastic materials for sealing washers. PTFE has low friction, high chemical resistance, and good non – stick properties, making it ideal for applications where chemical compatibility is crucial.

Fiber : Asbestos was once commonly used, but due to its health hazards, it has been largely replaced by non – asbestos fiber materials such as aramid fiber, carbon fiber, and cellulose fiber. These fiber – based sealing washers are used in applications where high – temperature resistance and good sealing performance are required.

Surface Treatment

Coating : A thin layer of material can be applied to the surface of the sealing washer to improve its performance. For example, a PTFE coating can be applied to a metal washer to reduce friction and improve chemical resistance. A rubber washer can be coated with a lubricant to make it easier to install and to prevent sticking.

Anodizing : This is a common surface treatment for aluminum sealing washers. Anodizing creates a hard, corrosion – resistant oxide layer on the surface of the aluminum, improving its durability and resistance to wear.

Plating : Metal washers can be plated with materials such as zinc, nickel, or chrome. Plating provides corrosion protection and can also enhance the appearance of the washer.

Combination Forms of metal sealing washer, nylon sealing washers

Composite Washers : These are made by combining different materials. For example, a rubber – coated metal washer combines the strength of the metal with the sealing properties of the rubber. Another example is a fiber – reinforced rubber washer, where the fiber provides additional strength and stability to the rubber.

Stacked Washers : Multiple washers can be stacked together to increase the sealing effectiveness. This is often used in applications where a higher sealing pressure is required or where the mating surfaces are not perfectly flat.

Integrated Washers : Some sealing washers are integrated with other components, such as bolts or nuts. For example, a self – sealing bolt may have a built – in rubber washer at the head to provide a seal when the bolt is tightened.

Functions of Metal Bonded Sealing Washer

Leak Prevention : The primary function of a sealing washer is to prevent the leakage of fluids or gases between two mating surfaces. It creates a tight seal that blocks the passage of substances, ensuring the proper functioning of the system.

Vibration Damping : Sealing washers can absorb vibrations and shocks, reducing the impact on the connected components. This helps to prevent damage and extend the service life of the equipment.

Corrosion Protection : By preventing the ingress of moisture and other corrosive substances, sealing washers can protect the mating surfaces from corrosion. This is especially important in environments where corrosion is a major concern.

Alignment and Support : Some sealing washers can also help to align the mating components and provide support, ensuring that they are properly positioned and functioning correctly.

Case Examples of Metal Bonded Sealing Washer

Automotive Engines : Sealing washers are used in various parts of an automotive engine, such as the cylinder head gasket, oil pan gasket, and valve cover gasket. These gaskets prevent the leakage of coolant, oil, and combustion gases, ensuring the efficient operation of the engine.

Plumbing Systems : In plumbing, sealing washers are used in faucets, pipes, and fittings to prevent water leakage. For example, a rubber washer in a faucet cartridge seals the connection between the cartridge and the valve body, preventing water from dripping.

Hydraulic Systems : Hydraulic systems require high – pressure sealing to prevent the leakage of hydraulic fluid. Metal and rubber sealing washers are used in hydraulic cylinders, pumps, and valves to ensure the proper functioning of the system.

Electrical Enclosures : Sealing washers are used in electrical enclosures to prevent the ingress of dust, moisture, and other contaminants. This helps to protect the electrical components inside the enclosure and ensures their reliable operation.

Reviews

There are no reviews yet.