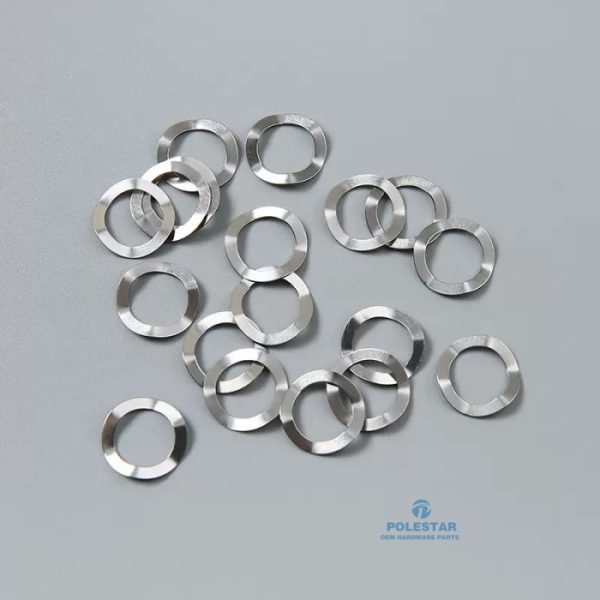

Custom Spring Washers Carbon Steel Stainless Steel Phosphor Bronze Beryllium Copper

Custom Spring Washers Carbon Steel Stainless Steel Phosphor Bronze Beryllium Copper

- Description

- Reviews (0)

Description

Custom Spring Washers Carbon Steel Stainless Steel Phosphor Bronze Beryllium Copper

Spring Washers – Technical Specifications

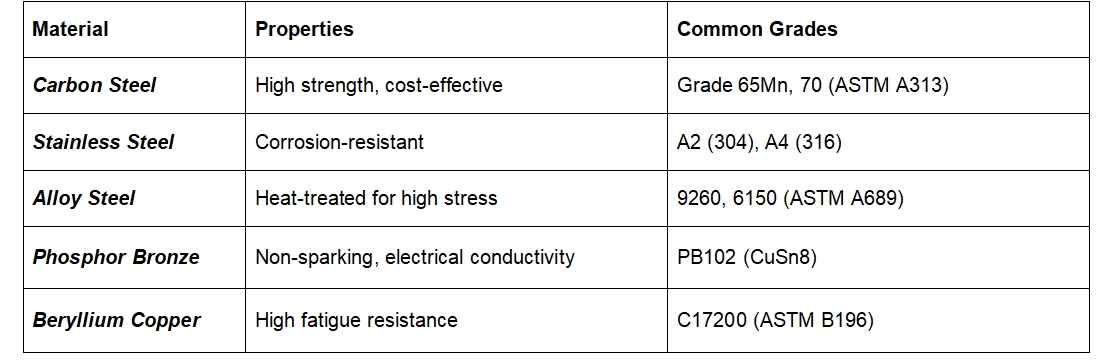

Common Materials

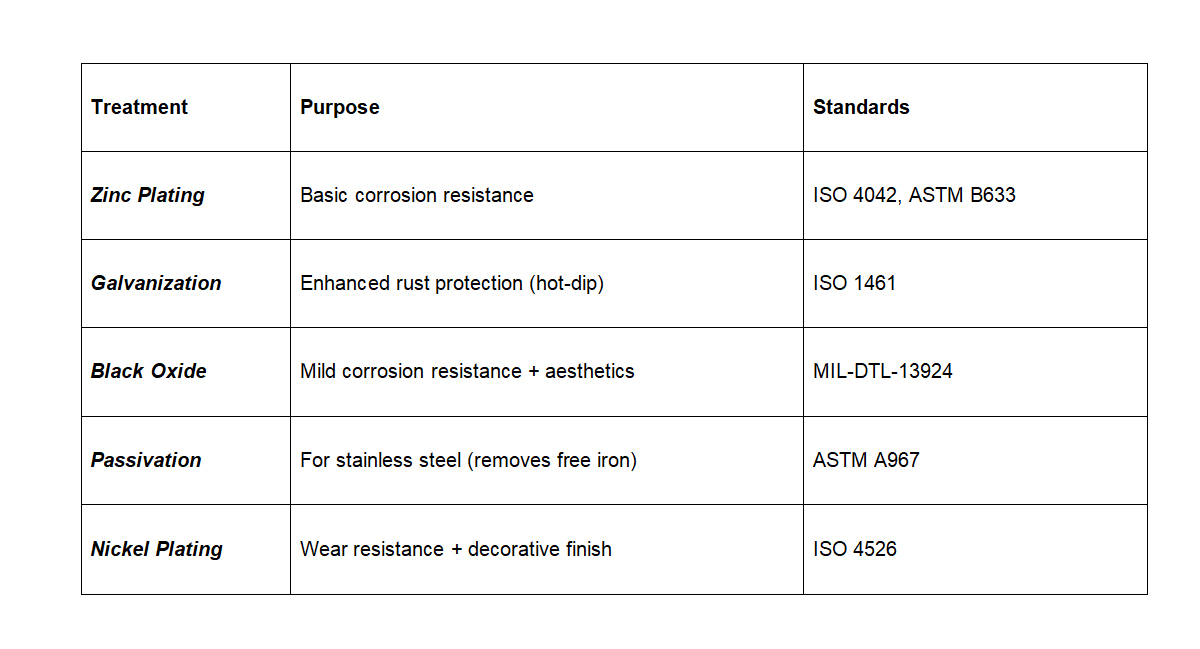

Surface Treatments

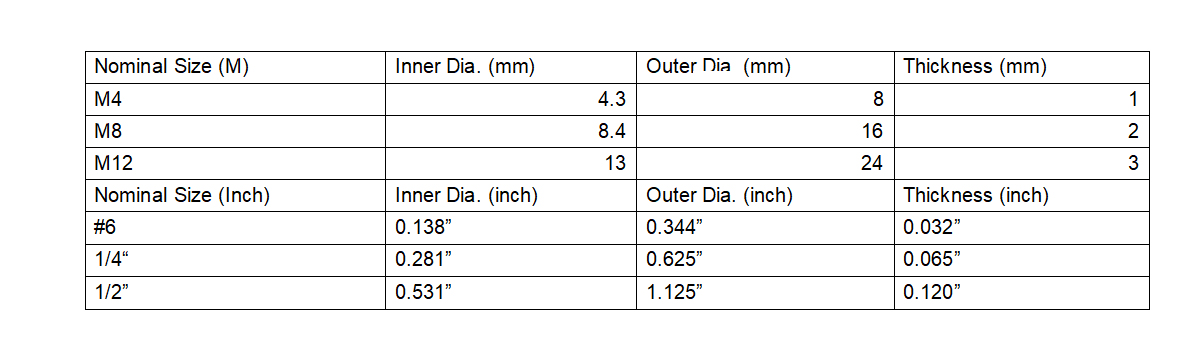

Standard Sizes & Specifications

Metric & Inch Sizes

Mechanical Properties

Spring Rate : 50–300 N/mm (varies by material/size).

Hardness :

Carbon steel: 40–50 HRC

Stainless steel: 30–40 HRC

Temperature Range :

Carbon steel: -30°C to +120°C

Stainless steel: -200°C to +400°C

Applications

Selection Guide

Vibration Resistance : Choose helical (single-coil) spring washers (DIN 127).

High Loads : Use Belleville washers (conical design, per DIN 6796).

Corrosive Environments : Opt for A4 (316) stainless steel + passivation.

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Reviews

There are no reviews yet.