Custom Plain Washer Flat Washers With Special Surface Treatment Finish

Custom Plain Washers Flat Washer With Special Surface Treatment Finish

- Description

- Reviews (0)

Description

Custom Plain Washer Flat Washers With Special Surface Treatment Finish

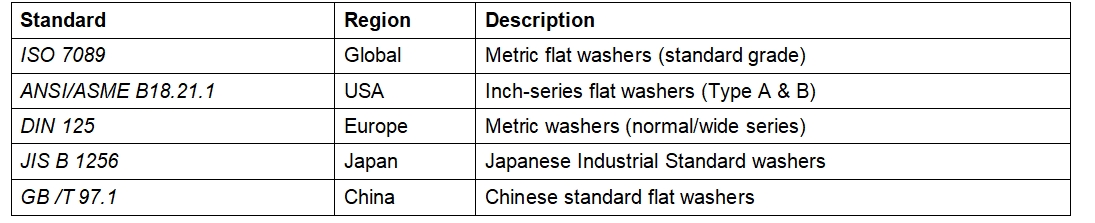

Common Standards & Norms

Common Sizes (Metric & Inch)

Material & Finish of Custom Plain Washer

Material & Finish of Custom Plain Washer

Materials :

Carbon steel (Grade 4.8, 8.8, 10.9)

Stainless steel (A2/AISI 304, A4/AISI 316)

Brass, aluminum, or plastic (for non-corrosive/light-duty use).

Finish :

Plain (uncoated), zinc-plated, galvanized, or black oxide.

Key Functions & Applications of Custom Plain Washer

Functions :

Distribute load under bolt/nut heads.

Prevent loosening from vibration.

Protect surfaces from damage during tightening.

Electrical insulation (non-metallic washers).

Applications :

Automotive assemblies (engine mounts, chassis).

Machinery (bearing housings, hydraulic systems).

Construction (steel structures, scaffolding).

Electronics (PCB mounting, grounding).

Selection Guide

Load Requirements : Thicker washers for high-stress applications.

Corrosion Resistance : Stainless steel for outdoor/marine use.

Temperature : A4 (316 SS) for extreme heat/chemical exposure.

Example Part Numbering (ISO 7089)

Stainless Steel Flat Washer (A2-70) :

ISO 7089 – M10 – A2

(Metric M10, stainless steel A2-70, standard thickness).

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Reviews

There are no reviews yet.