Custom Machined Nuts CNC Machined Threads for Vibration Resistance

Custom Machined Nuts CNC Machined Threads for Vibration Resistance

- Description

- Reviews (0)

Description

Custom Machined Nuts CNC Machined Threads for Vibration Resistance

Polestar Metal specializes in the production of custom non-standard fasteners, offering tailored solutions such as special surface treatments for standard components and bespoke machining for non-standard parts. With expertise in precision small-part customization, Polestar provides cost-effective solutions and has earned recognition from leading global corporations.

Here are several detailed case examples of Machined Nuts which Polestar Metal Solved:

- Aerospace Turbine Assembly

Nut Type: High-Temperature Lock Nut

Material: Inconel 718 (Nickel-Chromium Alloy)

Size: 3/8″-24 UNF

Key Features:

Withstands extreme heat (up to 1,300°F/700°C) in jet engines.

Precision-machined threads for vibration resistance.

Coated with dry-film lubricant to prevent galling.

- High-Speed Train Bogie Frame

Nut Type: Flanged Hex Nut

Material: Grade 10.9 Steel (Zinc-Nickel Plated)

Size: M24x3.0

Key Features:

Integrated flange distributes load across welded joints.

Corrosion-resistant coating for outdoor rail environments.

Torque-to-yield installation ensures consistent clamping force.

- Medical Imaging Equipment

Nut Type: Non-Magnetic Cap Nut

Material: Titanium (Ti-6Al-4V ELI)

Size: M6x1.0

Key Features:

MRI-compatible (zero magnetic interference).

Smooth, rounded cap protects patients from sharp edges.

Autoclavable for sterilization.

- Offshore Oil Rig Mooring System

Nut Type: Heavy-Duty Hex Nut

Material: ASTM A194 Grade 2H (Hot-Dip Galvanized)

Size: 1-1/2″-8 UNC

Key Features:

Resists saltwater corrosion and hydrogen embrittlement.

Machined to ±0.001″ tolerance for load-critical chains.

Paired with hardened washers to prevent seabed abrasion.

- Electric Vehicle Battery Pack

Nut Type: Conductive Copper Nut

Material: C11000 Electrolytic Copper

Size: M8x1.25

Key Features:

Ensures electrical grounding for battery modules.

Annealed for ductility to avoid thread cracking.

Nickel-plated to reduce oxidation.

- Industrial Robot Arm (6-Axis Joint)

Nut Type: Self-Aligning Spherical Nut

Material: Case-Hardened 4140 Steel

Size: M12x1.75

Key Features:

Compensates for angular misalignment in robotic joints.

Precision-ground spherical seat reduces wear.

Lubrication grooves extend service life.

Why These Cases Matter:

Precision: CNC-machined threads ensure consistent performance under stress.

Material Science: Alloys/finishes are tailored to operational demands (heat, corrosion, conductivity).

Safety-Critical: Failures in aerospace/medical apps can be catastrophic; nuts are rigorously tested.

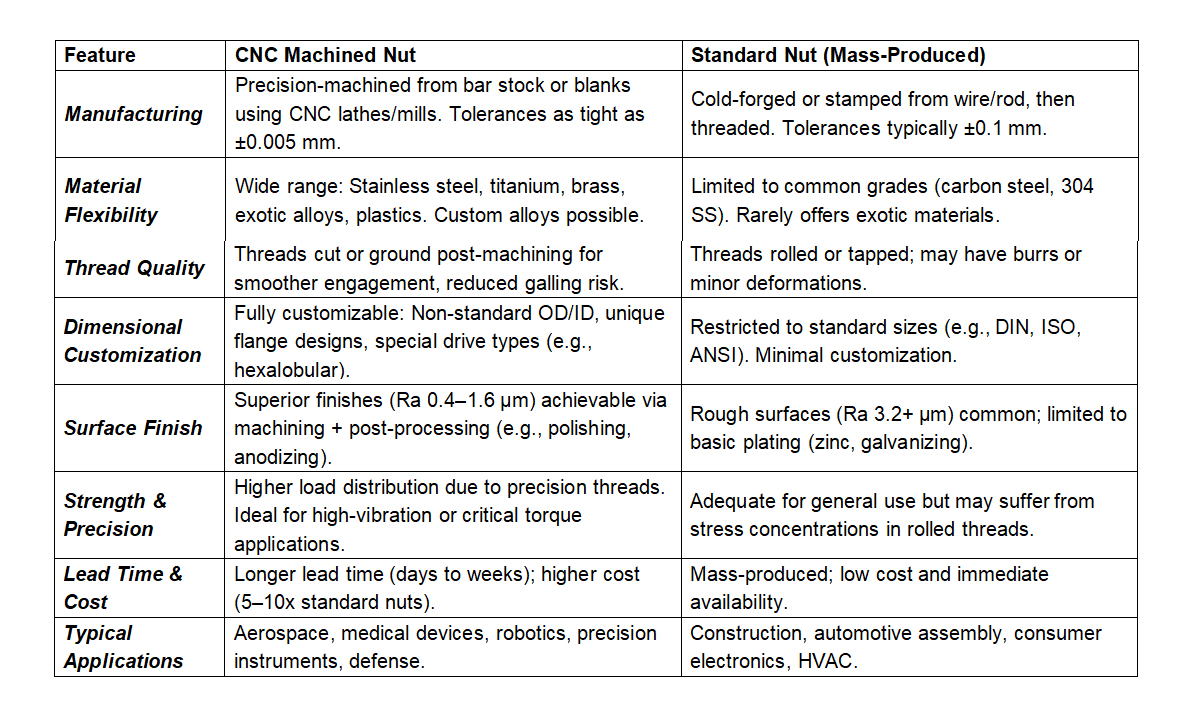

CNC Machined Nuts vs Standard Nuts

When to Choose Each Type?

CNC Machined Nuts:

Need exotic materials (e.g., Inconel, PEEK).

Require tight tolerances or non-standard geometries .

Critical environments: high temperature, corrosion, vacuum .

Standard Nuts:

High-volume projects with budget constraints .

Standardized assemblies (e.g., M6, 1/2″-13 UNC ).

Non-critical applications with low torque/vibration .

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Reviews

There are no reviews yet.